Tool Holder Clamping Cylinders and Actuators

BERG Spanntechnik manufactures a complete range of specially-designed tool unclamp cylinders and actuators. Cylinders include the OHL/OHLK and SE/SEK lines (designed not to load spindle bearings), to the all-electric ESK actuators.

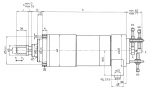

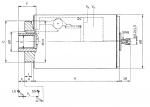

ESK Tool Clamping Cylinders

The electro-mechanical actuator is specifically designed for actuating the SSK gripper. This device generates both the clamping force, adjustable throughout a wide range, as well as the higher release force required for tool ejection. Up to a spindle rotational speed of 4000 rpm, the ESK clamping actuators are advantageous whenever the disadvantages of spring clamping are to be avoided and high clamping forces at relatively low rotational speed, as well as rigid spindle constructions are required. For their function they only require electrical energy which is available virtually everywhere.

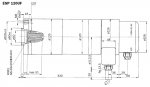

ESP UF Tool Clamping Cylinders

ESP UF electro-mechanical actuators are intended for the power actuated clamping and release of steep taper tooling on milling and boring machines on which the tool change is performed manually. They are firmly connected by way of appropriate connection pieces to the workspindle which has a maximum rotational speed of 4000 rpm. The electrical control can be per formed both manually and automatically.

HDT Tool Clamping Cylinders

HDT pressure intensifiers are primarily designed for tool clamping and chucking systems using stationary hydraulic cylinders of the type HLZ for releasing the tool shanks when no hydraulic unit is available for operating them.

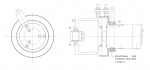

HLZ Tool Clamping Cylinders

HLZ hydraulic cylinders, in conjunction with spring actuated tool clamping and chucking devices, are intended for release and ejection of steep taper tooling and for stationary mounting.

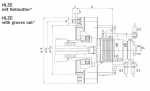

HLZE Tool Clamping Cylinders

HLZE hydraulic cylinders are designed for release and ejection of the tools in conjunction with spring actuated tool clamping devices and for stationary fitting. The HLZE series is used for applications in which the spindle bearing must not be submitted to the load of the actuation forces during tool changing.

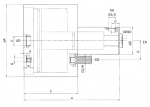

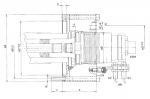

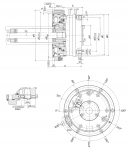

OHL and OHLK Tool Clamping Cylinders

Rotating hydraulic cylinders of the type OHLK..-1 and OHL..-1 are principally designed for actuating SK and HSK clamping sets. All coolant lubrication and compressed air supply variants are possible with a single device to meet the respective requirements. The control system is represented in the circuit diagram T 1345. Unlike spring actuated clamping and chucking systems, OHL(K) ..-1 hydraulic cylinders allow alteration of the clamping forces within wide limits. As the rotating cylinder is permanently connected to the spindle, no axial forces act upon the spindle bearings during tool release and ejection.

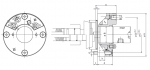

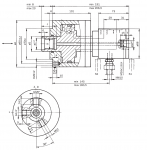

OSKL Tool Clamping Cylinders

OSKL rotating hydraulic cylinders are primarily designed for actuating SSK gripper, but are also suitable for operating other clamping and chucking systems.

SKVZ Tool Clamping Cylinders

SKVZ locking heads are designed for limiting the springing out resilience of the tools to the elastic yield of the connection elements when the axially acting cutting force components are larger than the clamping force on spring actuated tool clamping and chucking systems.