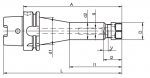

685.AZS-100-B50

Axial Collet Clamping Grippers for HSK 100 Grinding Wheels

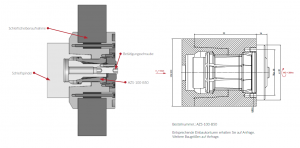

The AZS gripper is specially designed to manually mount heavy grinding wheels to a standard HSK 100 tool interface. The grinding wheel is mounted onto a HSK-style tool holder and is held to the spindle extremely accurately. The gripper allows very high clamping forces in a compact design. For example, the clamping force is 55 kN with a clamping torque of only 30 Nm for HSK 100. If needed, this AXS-100 gripper could be adapted for any HSK standard.

![]() PDF Data Sheet: Axial Collet Clamping Grippers for HSK 100 Grinding Wheels (685.AZS-100-B50)

PDF Data Sheet: Axial Collet Clamping Grippers for HSK 100 Grinding Wheels (685.AZS-100-B50)

The AZS gripper is specially designed to manually mount heavy grinding wheels to a standard HSK 100 tool interface.

The grinding wheel is mounted onto a HSK-style tool holder and is held to the spindle extremely accurately. The gripper allows very high clamping forces in a compact design. For example, the clamping force is 55 kN with a clamping torque of only 30 Nm for HSK 100.

If needed, this AXS-100 gripper could be adapted for any HSK standard.

For more information regarding this item (Axial Collet Clamping Grippers for HSK 100 Grinding Wheels) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

HSK Manual Clamping Grippers with Axial Drive

The Axialspanner comes for clamping disc-shaped tools (grinding wheels, saw blades) on HSK-flanges used. With low tension moments high clamping forces are generated, which are more than 50% above the recommended for HSK shanks values. Depending on the application of the AXS is centrally operated from the front through a tool flange or from the rear through the spindle.

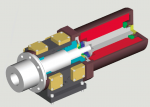

CBN Hydrostatic Grinding Spindle Systems

This is an example of a hydrostatic spindle designed for high speed grinding with CBN grinding wheels. The small bearing diameter in combination with high surface speed allows the use of CBN wheels even for undercuts in a camshaft application.

Tool Dynamic TD 800 Special Tool Balancing Systems

Based on the proven foundation provides the tool Dynamic Balancing Tool Dynamic TD 800, the balancing of large rotors of all types includes bearing rings, grinding wheels and turbine wheels. With tailor-made clamping adapters, balancing their rotors used quickly and easily.

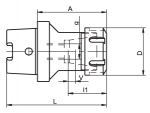

HSK-A Collet Holders

Available for HSK-A 32, 40, 50, 63, 80, 100

HSK-A Collet Holders (Sealed Version)

Available for HSK-A 32, 40, 50, 63, 80, 100

Hydrostatic Grinding Spindles with Integral Motors

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the workpiece. - Heat that is generated is moved immediately out of the spindle area with the oil and cooled in the chiller. - No vibration from roller bearings for extremely smooth operation. - Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.

HSK Axial-Clamping Manual Clamping Grippers

The Axial pliers Spanner is a manual HSK-tensioners with axially in the center lying indirect drive, which is accessible both from the front and from behind. It is particularly suitable for clamping of HSK, especially grinding wheel shots, with the AZS can be integrated into the hub of a wheel on the one hand, (HSK arranged vice versa - the spindle is the father) on the other hand, as usual, can be incorporated into the spindle using flange.

HSK-A Collet Chucks for ER/ESX ER-11/16 Collets with Internal Thread

Available for HSK-A 40, 50, 63, 100

HSK-C Collet Chucks for ER/ESX ER-25/32/40 Collets with Internal Thread

Available for HSK-C 63, 100