750.120

Workpiece Holding Systems Catalog

For more information regarding this item (Workpiece Holding Systems Catalog) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Steep Taper Spindle Gauge Manual

Download PDF for instruction manual.

Pallet Holding Force Gauges

Clamping force measuring gauges for pallets are intended to quickly measure the holding force of individual clamping heads.

Pallet clamping adapters are per-application based, and are fitted according to the specifications of the customer's pallet system.

Clamping adapters can be or have been provided for various pallet systems: BERG, Rohm, Mazak, OTT, Schunk, Erowa, and others.

Workpiece Holding Clamping Systems

BERG-Spanntechnik offers an extensive range of power operated chucks and hydraulic cylinders which meet all the requirements of modern CNC lathes as there are effective clamping force, attainable numbers of rotation, and precision, as well as center hole width for bar stock.

ForceCheck Workholding Collet Force Gauge

ForceCheck collet force gauges provide a quick and easy way to check force on collet workholding systems.

Applications for ForceCheck workholding collet force gauges include:

-Comparison of holding force between machines, allowing for consistent and repeatable production results regardless of mechanism (manual, hydraulic, or pneumatic)

-Periodic verification to assess if preventive maintenance is needed

-Establish correct holding force for running a particular part or job

-Determine optimal holding force for thin-wall, rings, and other parts sensitive to damage or distortion when machining

A sensor is needed for each diameter to be measured. A ForceCheck base set with display is needed to display results (order separately).

Sensors are also available in low-force versions. Contact us for further information.

Zero Master Digital Setup Indicator

The dial gauge indicates the distance between spindle axis and workpiece edge. As soon as the gauge shows zero, the spindle axis is exactly on the workpiece edge on the first attempt. This eliminates calculating or problems with positive or negative signs.

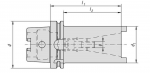

KS Adapter Flanges

Used for fitting onto machine spindle or in standard SK adapters for holding HSK tools. Available for HSK-C 32, 40, 50, 63, 80, 100

Workbench Tool Mounting Fixtures

682.126 mounting fixtures have been discontinued. Link below for available alternatives.

Mounting unit partially pre-assembled, aluminum body, holding sleeve, swivel unit and clamping elements. Available for HSK, Capto PSK (PSC), Steep Taper (SK), and VDI.

HSK to Steep Taper Adapters

Application: for holding steep taper tool holders in an HSK spindle.

KS Adapter Flanges for Short Spindles

With radial alignment. Used for fitting into short spindles (DIN 69002) for holding HSK tools. Available for HSK-C 32, 40, 50, 63.

Chuck Force Gauges - Wired

Designed to quickly check the holding force on a chuck or turning-center. The wired chuck force gauge can be customized for any diameter.