Master Setting / Center Height Gauges

To guarantee accurate and repeatable machine accuracy, various other components in the total machining process need to be correctly and accurately positioned. The Center Height Gauge allows the spindle center and spindle orientation to be checked. In addition, the gauge can also be used for tool presetter verification.

HSK Master Setting Gauges

| Taper | L (mm) | D (mm) | f1 (mm) | Part Number | ||||

|---|---|---|---|---|---|---|---|---|

| HSK-A/C/E/T 25 | Contact us | 455.110.125.000 | ||||||

| HSK-A/C/E/T 32 | Contact us | 455.110.132.000 | ||||||

| HSK-A/C/E/T 40 | 60 | 40 | 27 | 455.110.140.000 | ||||

| HSK-A/C/E/T 50 | 70 | 50 | 35 | 455.110.150.000 | ||||

| HSK-A/C/E/T 63 | 80 | 63 | 45 | 455.110.163.000 | ||||

| HSK-A/C/E/T 80 | 80 | 80 | 50 | 455.110.180.000 | ||||

| HSK-A/C/T 100 | 85 | 100 | 60 | 455.110.190.000 | ||||

| HSK-A/C/T 125 | 90 | 125 | 75 | 455.110.192.000 | ||||

| HSK-F63 63 | 80 | 63 | 45 | 455.110.663.000 | ||||

| HSK-F80 80 | 80 | 80 | 50 | 455.110.680.000 |

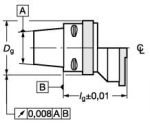

Steep Taper Master Setting Gauges

| Taper | Gauge Length | Diameter | fg | Part Number | ||||

|---|---|---|---|---|---|---|---|---|

| Steep Taper 40 (BT) | lg=65 | Dg=65 | 45 | 455.110.740.000 | ||||

| Steep Taper 50 (BT) | lg=65 | Dg=102 | 55 | 455.110.750.000 | ||||

| Steep Taper 40 (DIN) | lg=65 | Dg=65 | 45 | 455.110.840.000 | ||||

| Steep Taper 50 (DIN) | lg=65 | Dg=102 | 55 | 455.110.850.000 | ||||

| Steep Taper (CAT/ANSI) 40 | lg=65 | Dg=65 | 45 | 455.110.940.000 | ||||

| Steep Taper (CAT/ANSI) 50 | lg=65 | Dg=102 | 55 | 455.110.950.000 |

Capto Master Setting Gauges

| Taper | Gauge Length | Diameter | fg | Part Number | ||||

|---|---|---|---|---|---|---|---|---|

| Capto C3 | lg=40 | Dg=34 | 22 | 455.110.C03.000 | ||||

| Capto C4 | lg=50 | Dg=42 | 27 | 455.110.C04.000 | ||||

| Capto C5 | lg=60 | Dg=52 | 35 | 455.110.C05.000 | ||||

| Capto C6 | lg=65 | Dg=65 | 45 | 455.110.C06.000 | ||||

| Capto C8 and C8X | lg=80 | Dg=82 | 55 | 455.110.C08.000 | ||||

| Capto C10 | Contact us | 455.110.C10.000 |

KM Master Setting Gauges

| Taper | L (mm) | D (mm) | f1 | Part Number | ||||

|---|---|---|---|---|---|---|---|---|

| KM40 (ISO 26622) | 60 | 40 | 25 | 455.110.K40.000 | ||||

| KM50 (ISO 26622) | 60 | 50 | 35 | 455.110.K50.ISO | ||||

| KM63 (Integrex) | 65 | 63 | 45 | 455.110.K63.IGX | ||||

| KM6350 | 65 | 63 | 45 | 455.110.K65.000 | ||||

| KM63 (ISO 26622) | 65 | 63 | 45 | 455.110.K63.ISO | ||||

| KM80 (TS, ISO 26622) | 80 | 80 | 50 | 455.110.K80.ISO | ||||

| KM100 (ISO 26622) | 85 | 100 | 60 | 455.110.K90.ISO |