360.100

Overview: HAWE Hydraulic Components

HAWE Hydraulik (Heilmeier & Weinlein Fabrik fur Oelhydraulik GmbH & Co. KG), is a well-known German manufacturer of a wide range of hydraulic components.

![]() PDF Data Sheet: Overview: HAWE Hydraulic Components (360.100)

PDF Data Sheet: Overview: HAWE Hydraulic Components (360.100)

HAWE Hydraulik (Heilmeier & Weinlein Fabrik für Oelhydraulik GmbH & Co. KG) is a well-known German manufacturer of hydraulic components.

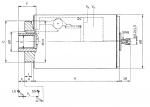

Compact hydraulic power packsTypes FP, HC, HCW, MP, MPW, and HK

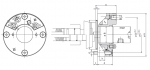

Standard pumps and unitsType R Radial Piston Pumps

Dual stage pumps and unitsTypes RZ and LP

Pneumatically operated hydraulic pumps

Hand pumpsTypes HD, HE, and DH

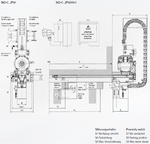

Directional spool valvesTypes SG, SP, SKP, SKH, SW, SWR, SWP, HSR, HSF, HSL, DL, PSL, and PSV

Directional seated valvesTypes VB, WH, WN, BWH, BWN, VZP, BVZP, EM, BVG, BVP, HSV, CR, VH, VHR, VHP, DA, and EA

Pressure valvesTypes MV, SV, CMV, CSV, DV, AS, VR, PMV, PDV, ADC, AM, ADM, VDM, CDK, PM, PDM, CNE2, NE, LV, ALZ, DSV, CDSV, LHK, and LHDV

Flow valvesTypes SF, SD, SK, SU, SB, SQ, SJ, SE, SEH, TQ, TV, EB, BE, BC, Q, QR, QV, FG, ED, RD, AV, AVT, and CAV

Check valvesTypes RK/RB, RC, RE, ER, CRK, CRB, B, CRH, RHC, HRP, RH, DRH, F, LB, WV, and WVC

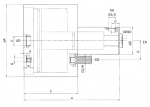

Hydraulic cylindersTypes HSE, HSA, BZ, P, PF, and PS

Hydraulic accessoriesTypes DG and AC

Electronic Accessories

Please contact us if you need further information on any of these products.

For more information regarding this item (Overview: HAWE Hydraulic Components) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Hydraulic Power Stations for Hydraulic Quick Die Clamping Systems

Hydraulic power stations for quick die clamping systems are designed for actuating hydraulic clamping elements in the forming presses. A large number of electro-hydraulic (HA) or air-hydraulic power stations (HAL) are available depending on the use of the clamping elements and/or hydraulics on the press plunger or on the table, as well as the number of clamping elements.

SKVZ Tool Clamping Cylinders

SKVZ locking heads are designed for limiting the springing out resilience of the tools to the elastic yield of the connection elements when the axially acting cutting force components are larger than the clamping force on spring actuated tool clamping and chucking systems.

ForceCheck Hydraulic Tool Holder Force Gauges

Hydraulic tool holders are an excellent ultra-low option with added benefits such as vibration damping and ease of use. One of the major challenges with hydraulic holders is determining if they are still functioning correctly over time. Failure of the hydaulic holding mechanism is often not apparent until cutter slippage occurs, potentially causing damage to both the holder and a scrapped workpiece.

ForceCheck hydraulic tool holder force gauges provide a quick and reliable way to verify a tool holder is still operating correctly. The sensor measures the force at the center of the hydraulic sleeve.

Using the gauge is as easy as inserting the sensor in the hydraulic holder. Once the actuation piston compresses the hydraulic fluid in the expansion sleeve, the resulting force is shown on a handheld digital display. The measured force can be compared to a new or known-good hydraulic tool holder.

HDT Tool Clamping Cylinders

HDT pressure intensifiers are primarily designed for tool clamping and chucking systems using stationary hydraulic cylinders of the type HLZ for releasing the tool shanks when no hydraulic unit is available for operating them.

Automatic Hydraulic C-clamping Systems

The C-clamping hydraulic die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the park position and the respective die. Hydraulic pressure is at a maximum 400 bar

Manual Hydraulic C-clamping Systems

The hydraulic C-clamp die clamping systems are designed for clamping tools and dies of different widths on press slides. The C-clamp is equipped with a non-return valve. The die clamps can be manually moved in the T-slot of the press slide between the parking position and the respective tool. Hydraulic pressure is at a maximum 400 bar.