Forming Technology: Clamping Systems for Quick Die Changing

BERG supplies quick die changing clamping systems, slide locking systems, clamping systems for moving bolsters and transfer couplings for forming machines.

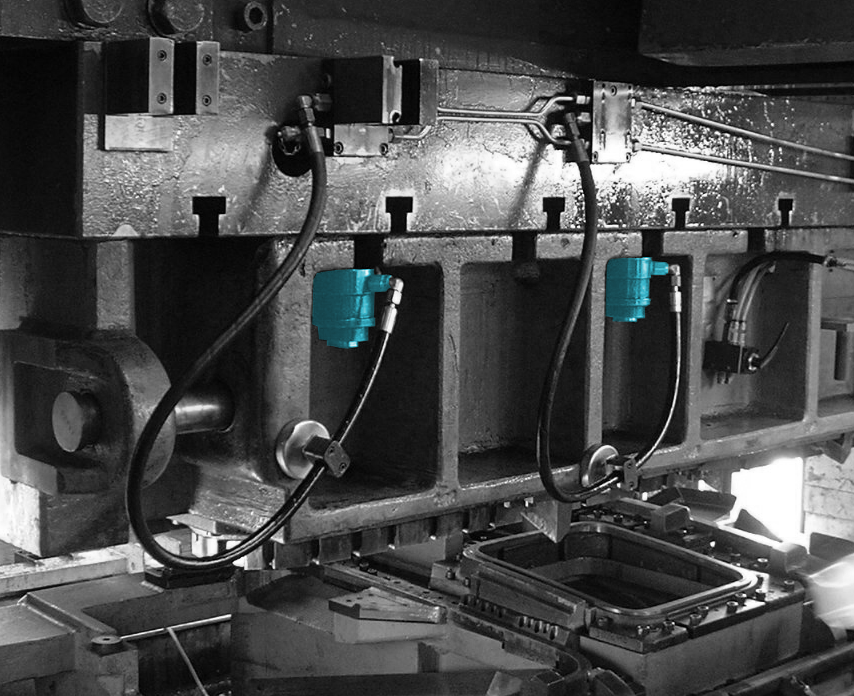

Complete automatic and manual clamping systems for quick die change presses from BERG Spanntechnik

Overview of AS-Interface Clamping Systems from BERG

The BERG AS-Interface clamping and chucking systems are intended for clamping various tools/dies on press slides and blank-holders, and for sliding table clamping and gripper rail couplings on multiple die presses. They are used on new machines and for retrofitting automatic clamping systems in existing press lines.

The BERG AS-Interface clamping and chucking systems are intended for clamping various tools/dies on press slides and blank-holders, and for sliding table clamping and gripper rail couplings on multiple die presses. They are used on new machines and for retrofitting automatic clamping systems in existing press lines.

With the introduction of BUS systems in forming technology / quick die changing systems, it seemed logical to operate new clamping systems with a BUS system. Following the current trend, BERG Spanntechnik have developed BUS compatible clamping systems based on AS-Interface with a logic module, which have already been proven in practice, feature the following advantages:

• Connection to all well-known PLC control systems and industrial PCs via industrially available AS-I-Master

• Connection to higher ranking field-buses by means of industrially available link modules

• Simple commissioning (start-up) due to integrated logic module and auto-configuration of the AS-I BUS

• Programmers do not require any detailed knowledge of the clamping system functions

• Integrated rotary field control prevents malfunctions

• Minimum installation and commissioning times

• High availability of all clamping elements and targeted error detection by a electronic diagnosis program

• Simple replacement of a clamping system due to automatic address programming

• EMC certified

• Simple retrofitting of forming machines / press clamping systems

• Minimum cable expenditure

• Minimum space required for external hardware in the switch cabinet

• Extremely low costs for external hardware in the switch cabinet

• Standardized signal exchange allows for the use of different clamping and chucking systems

• Maintenance-free due to full electronics

Stationary Clamping Systems

The stationary hydraulic quick die clamping system is designed to automatically clamp tools at the press slide or on the table. In the unclamped position, the tensioning rod is completely retracted into the clamping element and initially moved out of the clamping element when pressure is applied.

Self-Traveling Clamping Systems

Self-traveling clamping systems from BERG are designed to automatically lock and unlock dies from press slides. Depending on the quick die changing application, there are a variety of designs and mechanisms of the self-traveling clamping system.

Manual Clamping Systems

Manually-movable clamping systems are designed for manual and quick die changing. The units are supported by mechanical, hydraulic, and hydro-mechanical means.

Transfer Rail Couplings

Transfer rail couplings are designed to join and clamp the gripper rails on transfer presses. Manually operated, electromechanical, or hydro-mechanical locking can be used to support the system.

Quick Die Change Accessories

Accessories for quick die changing systems include hydraulic power stations and press clamping force gauges.