293-PSV-C

BERG Automatic Hydro-mechanical Self-locking C-clamping Systems

Self-traveling (Automatic) quick die changing system with self-locking C-clamping

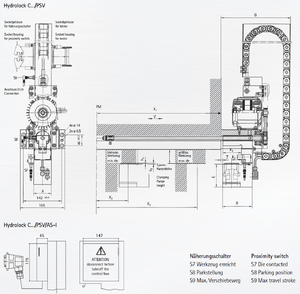

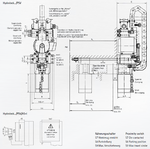

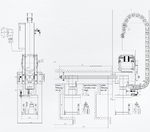

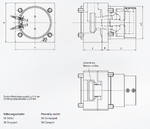

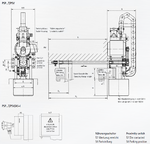

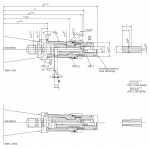

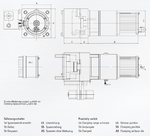

The C-clamping hydromechanical self-locking (hydrolock) die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the parking position and the respective die. Clamping and unclamping are performed by a hydromechanical self-locking clamping gear. Hydraulic pressure is at a maximum of 90 bar.

![]() PDF Data Sheet: BERG Automatic Hydro-mechanical Self-locking C-clamping Systems (293-PSV-C)

PDF Data Sheet: BERG Automatic Hydro-mechanical Self-locking C-clamping Systems (293-PSV-C)

For more information regarding this item (BERG Automatic Hydro-mechanical Self-locking C-clamping Systems) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Automatic Hydro-mechanical Self-locking Drawbar Style Clamping Systems

The drawbar style hydromechanical (hydrolock) self-locking die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the parking position and the respective die. Clamping and unclamping are performed by a hydromechanical self-locking clamping gear. Hydraulic pressure is at a maximum 90 bar.

Automatic Electromechanical Drawbar Style Clamping Systems

The electro-mechanical self-locking drawbar style clamping system is designed for quick clamping dies of different widths with clamping slot on press slides.

The clamping systems are controlled de-centrally and individually in each clamping system. Each local clamp control system communicates with the pressing machine control system. The clamping actuator automatically moves into the T-slot of the press slide between the parking position and the respective die. The electro-mechanical clamping system clamps the die and switches off automatically on reaching the clamping force.

Hydro-mechanical Self-locking Transfer Rail Couplings

The hydromechanical self-locking gripper rail coupling is designed for automatic coupling of gripper rails on transfer presses. A vertical lift-out stroke is required for changing the tool. The coupling consists of a hard anodized aluminum housing, an axially movable tensioning rod and a hydromechanical self-locking clamping gearing. This configuration allows for high clamping forces and features a very high dynamic rigidity with minimum mass.

Manual Hydro-mechanical Self-locking C-clamping Systems

The hydromechanical self-locking (hydrolock) C-clamping die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator can be moved manually in the T-slot of the press slide between the parking position and the respective die. Hydraulic pressure is at a maximum 90 bar.

Transfer Rail Couplings

The mechanical self-locking Berg gripper rail coupling GSM is designed for manual coupling of gripper rails on transfer presses. A vertical lift-out stroke is required for changing the tool.

Manual Hydro-mechanical Self-locking Drawbar Style Clamping Systems

The hydromechanical self-locking (hydrolock) drawbar style die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator can be moved manually in the T-slot of the press slide between the parking position and the respective die. Hydraulic pressure is at a maximum 90 bar.

Automatic Mechanical Disk Spring Washer Style Clamping Systems

The mechanical disk-spring washer style die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the park position and the respective die. Clamping is performed by belleville spring washers and hydraulic unclamping.

Steep Taper Grippers SSKV

The BERG Spanntechnik SSKV incorporates a number of new technical innovations, including tool holding force intensification and a special tribolic coating to ensure the highest possible constant clamping force.

Electromechanical Transfer Rail Couplings

The electro-mechanical gripper rail coupling is designed for automatic coupling of gripper rails on transfer presses. A vertical lift-out stroke is required for changing the tool. The coupling consists of a hard anodized aluminum housing, an axially movable tensioning rod and an electromechanical self-locking helical gearing. This configuration achieves a very high repeat precision, high clamping forces, and features dynamic rigidity with low mass.