HSK Tool Holder Dimensional Gauges

HSK Tool Holder Taper Inspection Gauge

Designed to detect tool holder taper wear in seconds.

The tool holder taper inspection gauge includes two Fixture Bases, two 0.001mm Indicators, and a carrying case. An optional 410.148 certified Taper Master is strongly recommended for zeroing the Indicators. If a master is not available, a known good tool holder can be used in place of the master.

<b>Additional product information can be found on the Details tab below.</b>

HSK Certified Master Taper Gauge

These taper master gauges can be used for zeroing the dial indicators on our HSK Tool Holder Inspection Gauges.

High Precision HSK Gauge Masters

To check the extremely small tolerances required by the DIN and ISO

standards for HSK tool holders.

| HSK-A/C/E Taper | HSK-B/D/F Taper | Part Number | ||||||

|---|---|---|---|---|---|---|---|---|

| HSK-A/C/E 25 | HSK-B/D/F 32 | 410.145.125.000 | ||||||

| HSK-A/C/E 32 | HSK-B/D/F 40 | 410.145.132.000 | ||||||

| HSK-A/C/E 40 | HSK-B/D/F 50 | 410.145.140.000 | ||||||

| HSK-A/C/E 50 | HSK-B/D/F 63 | 410.145.150.000 | ||||||

| HSK-A/C/E 63 | HSK-B/D/F 80 | 410.145.163.000 | ||||||

| HSK-A/C/E 80 | HSK-B/D/F 100 | 410.145.180.000 | ||||||

| HSK-A/C/E 100 | HSK-B/D/F 125 | 410.145.190.000 |

Series 978 HSK 30 Degree Clamping Angle Gauges

To ensure sustained accuracy at HSK interfaces, we recommend comparison measuring of the geometry of HSK tool shanks and spindles at regular intervals. These checks should become more frequent with an increased change rate at the interface.

| Taper | l1 | d1 | Part Number | |||||

|---|---|---|---|---|---|---|---|---|

| HSK-A/C/E 25 | 7.21 | 15 | 410.231.125.000 | |||||

| HSK-A/C/E 32 | 8.92 | 19 | 410.231.132.000 | |||||

| HSK-A/C/E 40 | 11.42 | 23 | 410.231.140.000 | |||||

| HSK 50 | 14.13 | 29 | 410.231.150.000 | |||||

| HSK-A/C/E 63 | 18.13 | 37 | 410.231.163.000 | |||||

| HSK-A/C/E 80 | 22.85 | 46 | 410.231.180.000 | |||||

| HSK-A/C/E 100 | 28.56 | 58 | 410.231.190.000 |

Pneumatic HSK Tool Holder Taper Gauge Kits

Gauging kit for HSK tool holder taper with pneumatic measuring column. The Multifunctional Measuring and Control Device is designed for high precision and multifunctional capabilities. In addition to providing various ways for measuring input, it can be customized to meet customer requirements.

HSK Tool Holder Taper 30 Degree Clamping Angle Gauges

Using the calibrated master, the distance of the 30 degree clamping slope relative to l 2 is preset using the dial indicator holder. The tool taper to be measured is placed in the centering piece, allowing the variation of the taper to be measured.

| HSK A/C/E | HSK B/D/F | l 6 / JS 10 | d 6 | Part Number | ||||

|---|---|---|---|---|---|---|---|---|

| HSK-A 25 | HSK 32 | 7.21 | 15 | 410.230.125.000 | ||||

| HSK-A 32 | HSK 40 | 8.92 | 19 | 410.230.132.000 | ||||

| HSK-A 40 | HSK 50 | 11.42 | 23 | 410.230.140.000 | ||||

| HSK-A 50 | HSK 63 | 14.13 | 29 | 410.230.150.000 | ||||

| HSK-A 63 | HSK 80 | 18.13 | 37 | 410.230.163.000 | ||||

| HSK-A 80 | HSK 100 | 22.85 | 46 | 410.230.180.000 | ||||

| HSK-A 100 | HSK 125 | 28.56 | 58 | 410.230.190.000 | ||||

| HSK-A 125 | HSK 160 | 36.27 | 73 | 410.230.192.000 | ||||

| HSK-A 160 | - | 45.98 | 92 | 410.230.196.000 |

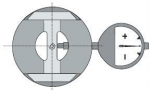

Series 410 Dial Indicator Tool Taper Gauges

Both measuring gauges are set to zero with the calibrated taper plug gauge. When an HSK tool holder is inserted in the ring gauges, deviations in diameters d2 or d3 are shown on the indicator.

| HSK A/C/E | HSK B/D/F | d2 | d3 | Part Number | ||||

|---|---|---|---|---|---|---|---|---|

| HSK-A 25 | HSK 32 | 19 | 18.15 | 410.210.125.000 | ||||

| HSK-A 32 | HSK 40 | 24 | 23.27 | 410.210.132.000 | ||||

| HSK-A 40 | HSK 50 | 30 | 29.05 | 410.210.140.000 | ||||

| HSK-A 50 | HSK 63 | 38 | 36.90 | 410.210.150.000 | ||||

| HSK-A 63 | HSK 80 | 48 | 46.53 | 410.210.163.000 | ||||

| HSK-A 80 | HSK 100 | 60 | 58.10 | 410.210.180.000 | ||||

| HSK-A 100 | HSK 125 | 75 | 72.60 | 410.210.190.000 | ||||

| HSK-A 125 | HSK 160 | 95 | 91.95 | 410.210.192.000 | ||||

| HSK-A 160 | - | 120 | 116.00 | 410.210.196.000 |

Series 968 HSK Tool Holder Taper Gauges

Series 968 gauges offer comprehensive dimensional verification of HSK tool holders.

| Taper | Diameter | Part Number | ||||||

|---|---|---|---|---|---|---|---|---|

| HSK-A/C/E 25 | 19 | 410.211.125.000 | ||||||

| HSK-A/C/E 32 | 24 | 410.211.132.000 | ||||||

| HSK-A/C/E 40 | 30 | 410.211.140.000 | ||||||

| HSK-A/C/E 50 | 38 | 410.211.150.000 | ||||||

| HSK-A/C/E 63 | 48 | 410.211.163.000 | ||||||

| HSK-A/C/E 80 | 60 | 410.211.180.000 | ||||||

| HSK-A/C/E 100 | 75 | 410.211.190.000 |

Electronic Tool Taper Gauges

The four transducers mounted in the measuring ring are used for differential measurement of gauge dimensions d2 and d3. Deviations from the calibrated taper plug gauge are shown on the two indicator columns.

| HSK A/C/E | HSK B/D/F | d2 | d3 | l2 | l3 | Part Number | ||

|---|---|---|---|---|---|---|---|---|

| Indicator Column | 410.220.000.000 | |||||||

| HSK-A 25 | HSK 32 | 19.000 | 18.1500 | 2.5 | 8.5 | 410.220.125.000 | ||

| HSK-A 32 | HSK 40 | 24.007 | 23.2755 | 3.2 | 7.3 | 410.220.132.000 | ||

| HSK-A 40 | HSK 50 | 30.007 | 29.0551 | 4.0 | 4.5 | 410.220.140.000 | ||

| HSK-A 50 | HSK 63 | 38.009 | 36.9068 | 5.0 | 11.0 | 410.220.150.000 | ||

| HSK-A 63 | HSK 80 | 48.010 | 46.5370 | 6.3 | 14.7 | 410.220.163.000 | ||

| HSK-A 80 | HSK 100 | 60.012 | 58.1082 | 8.0 | 19.0 | 410.220.180.000 | ||

| HSK-A 100 | HSK 125 | 75.013 | 72.6082 | 10.0 | 24.0 | 410.220.190.000 |

Tool Holder Drive Key Tool Taper Gauges

Available for HSK 32, 40, 50, 63, 80, 100, 125, 160