467.100

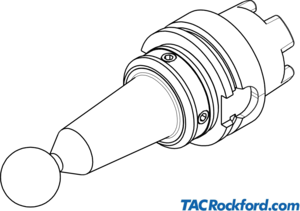

HSK Precision Ball-End Runout Test Arbors

For verification of 5-axis HSK taper spindle machining centers

Our 467 precision version feature an adjustment mechanism which allows for improved accuracy when compared to our standard 466 ball arbors.

![]() PDF Data Sheet: HSK Precision Ball-End Runout Test Arbors (467.100)

PDF Data Sheet: HSK Precision Ball-End Runout Test Arbors (467.100)

| Taper | Length (L) | Diameter (D) | Standard | Part Number | ||||

|---|---|---|---|---|---|---|---|---|

| HSK-A/C/E 32 + B/D/F 40 | 150 mm | 30 mm | DIN 69893 / ISO 12164 / ASME B5.62 | 467.132.000.000 | ||||

| HSK-A/C/E 40 + B/D/F 50 | 150 mm | 30 mm | DIN 69893 / ISO 12164 / ASME B5.62 | 467.140.000.000 | ||||

| HSK-A/C/E 50 + B/D | 150 mm | 30 mm | DIN 69893 / ISO 12164 / ASME B5.62 | 467.150.000.000 | ||||

| HSK-A/C/E 63 + B/D/F 80 | 150 mm | 30 mm | DIN 69893 / ISO 12164 / ASME B5.62 | 467.163.000.000 | ||||

| HSK-A/C 80 | 150 mm | 30 mm | DIN 69893 / ISO 12164 / ASME B5.62 | 467.180.000.000 | ||||

| HSK-A/C 100 | 150 mm | 30 mm | DIN 69893 / ISO 12164 / ASME B5.62 | 467.190.000.000 | ||||

| HSK-A 125 | 150 mm | 30 mm | DIN 69893 / ISO 12164 / ASME B5.62 | 467.192.000.000 | ||||

| HSK-F 63 | 150 mm | 30 mm | DIN 69893 / ISO 12164 / ASME B5.62 | 467.663.000.000 | ||||

| HSK-F 80 | 150 mm | 30 mm | Makino HSK Flange-Pin Spindles | 467.680.000.000 | ||||

| Custom Size/Length/Diameter | Contact us with your requirements | 467.100.SP |

Overview: Spindle Runout Arbor Carrying Cases

Whether your gauges need to be transported on a frequent basis, or need to be stored in one area for a period of time, we can offer a reliable solution.

Spindle Runout Test Arbor Instructions

One of the leading causes of tool breakage, part finish issues, tolerance control, and machine registration issues is excessive spindle runout.

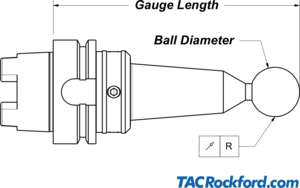

TAC Rockford precision ball arbors have a special adjustment mechanism which allows the ball runout to the taper to be adjusted.

Arbors are factory-adjusted to ≤0.005 mm (0.0002") runout. Runout adjustment fixtures are available for periodic verification and adjustment. A certificate of accuracy is included.

Gauge length is measured from the tool holder gauge line to the end of the ball. Please contact us for other ball diameters and gauge lengths. Inch dimensions are also available.

Arbors do not include a carrying case. Visit our carrying case options page for gauge crib upright storage, travel, and customized carrying case solutions.

For more information regarding this item (HSK Precision Ball-End Runout Test Arbors) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

KM Precision Ball-End Runout Test Arbors

Ball end spindle runout test arbors are designed checking positioning accuracy of 5-axis machines, but can also be used in place of a standard runout test bars when a shorter length is required or for a touchoff point from the spindle face (ball end is ideal for this purpose).

Our 467 precision version feature an adjustment mechanism which allows for improved accuracy.

* ISO 26622 runout arbor tapers are compatible with machines using TS, XMZ (Mazak Integrex), and ATC. Flange may not be suitable for use with automatic tool changers.

PSC Precision Ball-End Runout Test Arbors

Ball-end arbors are typically used on 5-axis machining centers.

Our 467 precision version feature an adjustment mechanism which allows for improved accuracy

Steep Taper Precision Ball-End Runout Test Arbors

Our 467 precision version feature an adjustment mechanism which allows for improved accuracy when compared to our standard 466 ball arbors.

HSK Standard Ball-End Runout Test Arbors

Ball end spindle runout test arbors are designed checking positioning accuracy of 5-axis machines, but can also be used in place of a standard runout test bars when a shorter length is required or for a touchoff point from the spindle face (ball end is ideal for this purpose).

Steep Taper Standard Ball-End Runout Test Arbors

Ball end spindle runout test arbors are designed checking positioning accuracy of 5-axis machines, but can also be used in place of a standard runout test bars when a shorter length is required or for a touchoff point from the spindle face (ball end is ideal for this purpose).

HSK Spindle Runout Test Arbors

- Maximum runout error 0.003mm / 3 micron / 0.00012 inch.

- Carrying cases are not included. Visit Data Sheet 465.006 for available case styles.

- A certificate of accuracy is included. Traceable certificates available; contact us for details.

- Contact us for other lengths, tapers, and other special requirements.

PSC / PSK Taper Standard Ball-End Runout Test Arbors

Precision Spindle Analysis for 5-Axis Machining

Ensure the highest levels of accuracy and performance from your machine tools with the TAC Rockford PSC (Polygonal-Shank Taper) Ball End Test Arbor. Specifically designed for the verification of 5-axis machining centers, this precision instrument is essential for maintaining spindle health and positioning integrity.

Key Features:

PSC Taper Standard: Built to the ISO 26623 Standard for seamless integration and accurate seating in your PSC spindle.

5-Axis Positioning Accuracy: Primarily used for precisely checking the positioning accuracy of 5-axis spindles, especially the Rotary Tool Center Point (RTCP).

Spindle Runout Verification: Functions as a highly accurate runout test arbor to quickly and easily check that your machine spindle is running true.

Versatile Ball End: The precision ball end is ideal for establishing a consistent and repeatable touch-off point from the spindle face, a critical step for machine setup and calibration. It also provides a shorter alternative to standard runout bars when required.

Precision and Reliability: TAC Rockford's commitment to quality ensures a reliable instrument for periodic performance checks, verification after a machine crash, or installation/relocation.

Included Certificate of Accuracy: Each arbor comes with a certificate of accuracy to confirm its adherence to strict quality standards.

PSC / PSK Spindle Runout Test Arbors

Made to the ISO 26623 Standard. Maximum runout error 0.003mm / 3 micron / 0.00012”. A certificate of accuracy is included. Storage are cases not included.