240.435

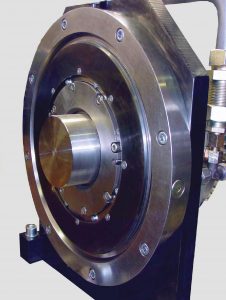

Hydrostatic Center Bearings

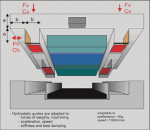

Hydrostatic Center Bearings for Turning Machines

- Only one radial bearing - Moment and axial forces are carried by an axial bearing - Integrated clamping piston and rotating oil union for a hydraulic collet. The clamping piston is driven with hydrostatic oil and released with springs. - Extremely minimal friction (results in minimal warming during continuous operation, and more of the motor drive force applied to the workpiece).

Construction and attributes of hydrostatic center bearings • Only one radial bearing

• Moment and axial forces are carried by an axial bearing

• Integrated clamping piston and rotating oil union for a hydraulic collet. The clamping piston is driven with hydrostatic oil and released with springs.

• Extremely minimal friction (results in minimal warming during continuous operation, and more of the motor drive force applied to the workpiece).

• Any minimal heat buildup is immediately carried out of the spindle via oil and is cooled at the hydraulic unit.

• No vibration (as can result from balls in bearings) provides for extremely silent operation.

• Excellent damping of oscillations created by machining operations, resulting in very good surface finish, improved cutter life (especially beneficial when turning hard materials).

• Very high axial and radial stiffness (high dimensional accuracy when finishing; inaccuracies from pre-machining are quickly equalized; excellent roundness of finished diameters even with interrupted cuts).

• RPM-independent stiffness and loadability (workpiece speeds of 0 to max. RPM are possible).

• Wear-free because there is no contact between surfaces.

• No loss of accuracy under maximum loads.

• No sensitivity to dirt because the bearings are continuously cleaned.

• Gap seals are backed up with purge air to protect the hydrostatic system from cutting fluids.

• The spindle is supplied with a customized hydraulic power unit with oil cooling capability and integrated bearing protection in the event of power failure.

• Can be driven by belt or gear drive.

• Static and dynamic bearing forces from cutting or unbalance can be monitored by measuring pressure in the hydrostatic pockets.

Technical DetailsWorking speed: 0-3000 RPM

Duty at 3000 RPM: approx. 3.0 kW

Max. pump duty: 3.5 kW

Pump pressure: 63 bar

Max. oil flow, bearing: 18 l/min

Max. oil flow, clamping cylinder: 8 l/min

Max. oil temp. increase at 3000 RPM: 12 deg. C

Spindle passage: 115 mm

For more information regarding this item (Hydrostatic Center Bearings) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Application: Hydrostatic Rotary Tables

The world's largest gear and profile grinding machines use hydrostatic bearings.

Hydrostatic Universal Bearings

- Frictionless even at minute revolutions

- Transmits minute rotating motion

- No backlash when reversing direction

- Slip-stick effect is eliminated

Hydrostatic Lathe Spindles

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the

workpiece. Heat that is generated is moved immediately out of the spindle area with the oil and cooled in the chiller.

- No vibration from roller bearings for extremely smooth operation.

- Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.

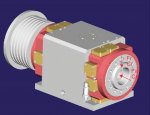

Hydrostatic Grinding Spindles with Integral Motors

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the

workpiece.

- Heat that is generated is moved immediately out of the spindle area with the oil and

cooled in the chiller.

- No vibration from roller bearings for extremely smooth operation.

- Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.

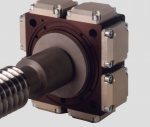

Hydrostatic Linear Motor Guide

The PM Flow Controller makes it possible for machine builders to easily integrate custom hydrostatic systems into both new and existing machines.

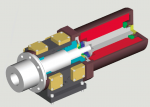

CBN Hydrostatic Grinding Spindle Systems

This is an example of a hydrostatic spindle designed for high speed grinding with CBN grinding wheels. The small bearing diameter in combination with high surface speed allows the use of CBN wheels even for undercuts in a camshaft application.

Hydrostatic Application Worksheet

Download the PDF data sheet for the Hydrostatic Application Worksheet