470.210.163.000

Drawbar Sensor Position Gauge for HSK-A/E63, Adjustable

| Product | Gauge |

| Part Type | Drawbar Sensor Position |

| Taper / Standard | HSK-A/E |

| Taper Size | 63 |

| Taper | Part Number | |||||||

|---|---|---|---|---|---|---|---|---|

| HSK-A/E 40 | 470.210.140.000 | |||||||

| HSK-A/E 50 | 470.210.150.000 | |||||||

| HSK-A/E 63 | 470.210.163.000 |

For more information regarding this item (Drawbar Sensor Position Gauge for HSK-A/E63, Adjustable) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

HSK Drawbar Sensor Position Gauges

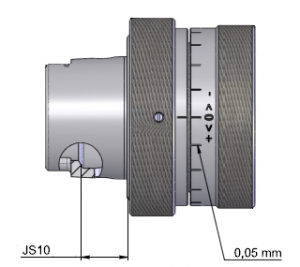

Drawbar position gauges are used to adjust and set drawbar stroke position on HSK machine tool spindles. The gauges allow the clamping angle to be adjusted to the high and low limits, allowing the stroke position to be set.

HSK Drawbar Stroke Gauge Sets

The dimension L5 per DIN69893 and ISO12164 defines the position of the clamping shoulder, toleranced to JS10. Our set of clamping shoulder gauge masters allows the position of automatic clamping systems with position sensors to be verified.

Set includes certified "zero" master, and two out-of-tolerance tapers (plus and minus). Out-of-tolerance tapers are approx. 3x the allowable limit.

Machine-Integrated Drawbar Force Gauges

The machine-integrated drawbar force gauge automates drawbar force measurement. With a wireless force sensor stored in the tool changer, a machine can periodically automatically check the drawbar without stopping production. Drawbar force is returned to the machine control via a wireless receiver, automatically alerting the operator if insufficient force is detected.

HSK-E Tool Holder Blanks

TAC Rockford stocks HSK-E32, HSK-E40, HSK-E50, and HSK-E63 blanks in a variety of diameters and lengths. Other sizes are available

- contact us with your requirements.

3D New Generation Setup Indicator

The 3D-Sensor NG is a further development of our worldwide accepted and proven Universal 3D-Sensor. Its distinguishing features are improved mechanics and a new and compact design.

HSK Taper Wireless Force Measuring Bars

Wireless measuring adapters have the option of coming with or without the tool change groove. Wireless adapters can be retrofitted for quick inspection or designed for integrated use; ask us more for details.

Electronic Tool Taper Gauges

The four transducers mounted in the measuring ring are used for differential measurement of gauge dimensions d2 and d3. Deviations from the calibrated taper plug gauge are shown on the two indicator columns.

HSK Taper ForceCheck Wireless Drawbar Force Sensors

The ForceCheck wireless drawbar force gauge is based on the same technology as the industry-leading ForceCheck gauge. With the added convenience of wireless operation, larger machines and hard-to-reach spindles are easier to check. In addition, the unit offers the optional capability of data logging on a USB stick.

3D Universal Setup Indicator

Short and long probes are available. The sensor probes may be changed without any tool. No re-calibration of the unit is needed during a sensor probe change over. Simply bring the needle to Zero, and that is your edge with any probe. The accuracy is such that you are able to inspect your parts right on the machine.

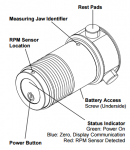

Wireless Chuck Force Sensor Manual

The ForceCheck chuck force gauge is designed to measure the clamping forces created by a chuck. The wireless sensor can be used for either static (non-rotating) or dynamic (rotating) measurements. When rotating, the sensor can also measure RPM (Revolutions Per Minute).