410.312.190.000

HSK-A/C 100 Spindle Taper Gauge

| Part Number | ||||||||

|---|---|---|---|---|---|---|---|---|

| HSK-A/C/E 63 | 410.312.163.000 | |||||||

| HSK-A/C/E 80 | 410.312.180.000 | |||||||

| HSK-A/C 100 | 410.312.190.000 | |||||||

| HSK-A 125 | 410.312.192.000 | |||||||

| HSK-F 63 | 410.312.663.000 | |||||||

| HSK-F 80 | 410.312.680.000 |

For more information regarding this item (HSK-A/C 100 Spindle Taper Gauge) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Steep Taper Spindle Gauge Manual

Download PDF for instruction manual.

Steep Taper Spindle Taper Dial Indicator Gauge

TAC Rockford's steep taper spindle gauge is designed to verify and measure correct location of the spindle gauge line.

Not included are an indicator and taper sleeve master.

The gauge can be used with any dial indicator with an 8mm stem. Recommended available options:

Part Nr. 499.220.150

- 0.01mm Resolution

Part Nr. 499.220.151

- 0.001mm Resolution

Part Nr. 499.220.155

- 0.00005" Resolution

In addition, we strongly recommend a 430.110 series Taper Sleeve Gauge to zero the indicator.

Drive Key Spindle Gauges

When inserted in the spindle, the "go" gauge should be in contact with the plane face. The "no go" gauge should not contact the face. Two measuring gauges in storage case: "go" and "no go" plug gauges.

HSK Tool Holder Taper Inspection Gauge

Designed to detect tool holder taper wear in seconds.

The tool holder taper inspection gauge includes two Fixture Bases, two 0.001mm Indicators, and a carrying case. An optional 410.148 certified Taper Master is strongly recommended for zeroing the Indicators. If a master is not available, a known good tool holder can be used in place of the master.

<b>Additional product information can be found on the Details tab below.</b>

Tool Holder Drive Key Tool Taper Gauges

Available for HSK 32, 40, 50, 63, 80, 100, 125, 160

Drawbar Stroke Verification Gauges

Prevents gripper failures, spindle and tool holder taper damage, and "stuck" tool holders.

HSK Dial Indicator Spindle Taper Gauge Manual

Instruction manual for the dial indicator spindle taper gauge (410.310)

HSK Tool Changer Alignment Gauges

Available for HSK-A 25, 32, 40, 50, 63, 80, 100, 125, and 160. Includes padded storage case.

Steep Taper Spindle Plug Gauges

TAC Rockford gauges are used for inspection of steep taper spindle tapers per CAT, ISO, JIS, DIN, etc. Available for Steep Taper 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 65

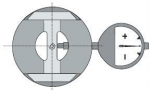

Dial Indicator Spindle Taper Gauges

To ensure sustained accuracy at HSK interfaces, we recommend comparison measuring of the geometry of HSK tool shanks and spindles at regular intervals. These checks should become more frequent with an increased change rate at the interface. Calibration on request.