410.330

Drive Key Spindle Gauges

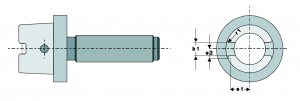

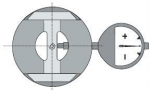

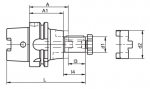

Measuring HSK spindle drive keys and radius

When inserted in the spindle, the "go" gauge should be in contact with the plane face. The "no go" gauge should not contact the face. Two measuring gauges in storage case: "go" and "no go" plug gauges.

| Taper | b1±0.05 | r1±0.025 | e1 | e2 | Part Number | |||

|---|---|---|---|---|---|---|---|---|

| HSK-A 32 | 6.8 | 1.5 | 8.905 | 4.903 | 410.330.132.000 | |||

| HSK-A 40 | 7.8 | 2.0 | 11.081 | 5.903 | 410.330.140.000 | |||

| HSK-A 50 | 10.3 | 2.5 | 13.997 | 7.648 | 410.330.150.000 | |||

| HSK-A 63 | 12.3 | 3.0 | 18.110 | 9.150 | 410.330.163.000 | |||

| HSK-A 80 | 15.8 | 4.0 | 22.073 | 11.898 | 410.330.180.000 | |||

| HSK-A 100 | 19.78 | 5.8 | 27.561 | 14.888 | 410.330.190.000 | |||

| HSK-A 125 | 24.78 | 6.0 | 35.580 | 18.388 | 410.330.192.000 | |||

| HSK-A 160 | 29.78 | 8.0 | 44.538 | 22.888 | 410.330.196.000 |

Two measuring gauges in storage case: "go" and "no go" plug gauges.

Note: center deviation of b1 (0.05 mm) is not measured.

Function

When inserted in the spindle, the "go" gauge should be in contact with the plane face. The "no go" gauge should not contact the face.

For more information regarding this item (Drive Key Spindle Gauges) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Tool Holder Drive Key Tool Taper Gauges

Available for HSK 32, 40, 50, 63, 80, 100, 125, 160

Mounting Nuts for HSK-A/C Interface Adaption

Can be mounted in front of the spindle shaft after the installation of the collet. Has the advantage of being adaptable to HSK-E or HSK-F tool interfaces in an HSK-A spindle. Just use the drive key to expand and then clamp the desired tool. The ENS slot nuts can also be used in manual clamping units for more flexibility. Available for HSK 32, 40, 50, 63, 80, and 100.

HSK Tool Holder Drive Key Gauge Manual

Measuring gauge for HSK tool holder taper drive key slots according to ISO 12164-1 (comparison measurement).

Download or print PDF data sheet for complete instructions.

Morse Spindle Taper Plug Gauges

TAC Rockford Morse spindle taper gauges are for inspection of Morse spindle tapers. Gauges made from a hardened gauge steel, and include a certificate. Manufactured per DIN 229.

HSK-A Shell End Mill Arbors for Milling Cutters with Longitudinal Slot or Tenon Drive

Available for HSK-A 40, 50, 63, 80, 100

Lathe Spindle Face Ring

Series 492.026 ring gauges are for lathe spindle face.

Ring only: order plug gauge separately (see series 492.028 or 492.228)

Steep Taper Spindle Plug Gauges

TAC Rockford gauges are used for inspection of steep taper spindle tapers per CAT, ISO, JIS, DIN, etc. Available for Steep Taper 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 65

HSK Standard Ball-End Runout Test Arbors

Ball end spindle runout test arbors are designed checking positioning accuracy of 5-axis machines, but can also be used in place of a standard runout test bars when a shorter length is required or for a touchoff point from the spindle face (ball end is ideal for this purpose).

Machine Tool Service Kits

Machine tool service kits from TAC Rockford include all common preventive gauges for a specific machine tool taper in one convenient kit.

Kits are customized to a specific machine taper and include drawbar pullforce gauges, runout test arbors, tool changer alignment tool, spindle taper gauge¹ and accessories such as a spindle taper wiper. Contact us for gauges included

Already have some of the gauges? We can customize a kit with only the additional items needed.

Looking for a different combination of gauges? We can customize a kit to fit your specific requirements.

¹Taper gauge included with steep taper only, optional for HSK