Hydrostatic Systems and Components

We are a Sales and Engineering Representative of Hyprostatik Schonfeld GmbH of Goppingen, Germany. The Hyprostatik PM-Flow Controller and hydrostatic components have been implemented in over 4,000 varied types of precision machine tools and components including grinding machines, measuring machines, high-speed machines, CNC lathes, machining centers, and milling machines, as well as large bearings and spindles.

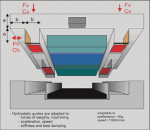

Hyprostatik can engineer a hydrostatic system to nearly any machine design requirement. A complete hydrostatic system from Hyprostatik uses the PM-Flow Controller and engineering specifications and instructions for a series of strategically placed pockets which are machined into moving surfaces of the machine by the machine builder. Variables such as pocket surface area, oil viscosity, pump pressure, and flow control are taken into account when designing for a defined gap size, load capacity and stiffness requirement.

The oil used in the hydrostatic system is the same oil that is used in the hydraulic system on the machine. Very little oil is used in the hydrostatic system, and a collection system designed into the machine re-circulates the small amount of accumulating oil through an oil filtration system. The PM-Flow Controller maintains a steady-state oil pressure in the hydrostatic pathways necessary to support a load, regardless of grinding or cutting stress, the weight of a workpiece, or its location.

Hydrostatic Application Worksheet

Download the PDF data sheet for the Hydrostatic Application Worksheet

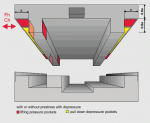

Hydrostatic Slides

- Very low friction, no friction at positioning

- Movement of 0.1 micro-m possible

- No reversal backlash of friction force

Hydrostatic Linear Motor Guide

The PM Flow Controller makes it possible for machine builders to easily integrate custom hydrostatic systems into both new and existing machines.

Application: Hydrostatic Linear Motor Guide

Linear motors are used on high-speed machine tools with high acceleration and slide speeds. For slides with linear motors, HYPROSTATIK has developed hydrostatic guideways that have no wear, excellent damping characteristics, high stiffness and much lower friction when compared with ball or roller rails.

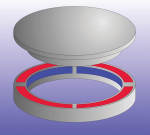

Hydrostatic Rotary Tables

Application example of a glass grinding machine used at Zeiss.

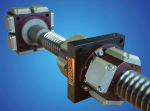

Hydrostatic Leadscrews

- Speed comparable to a linear motor

- Very low friction when machining, virtually frictionless

during positioning

- Steps in the 0.1 micron range are possible

- No backlash when reversing direction

Comparison: Hydrostatic Leadscrews, Linear Motors, and Ballscrews

Design limitations and problems in ballscrew applications lead to the development of linear motors and to wear-free hydrostatic leadscrews. In

this article we introduce the hydrostatic leadscrew system from HYPROSTATIK

Schönfeld GmbH and compare its technical features with linear motor drives

and ballscrews.

Hydrostatic Universal Bearings

- Frictionless even at minute revolutions

- Transmits minute rotating motion

- No backlash when reversing direction

- Slip-stick effect is eliminated

Hydrostatic Center Bearings

- Only one radial bearing

- Moment and axial forces are carried by an axial bearing

- Integrated clamping piston and rotating oil union for a hydraulic collet. The clamping piston is driven with hydrostatic oil and released with springs.

- Extremely minimal friction (results in minimal warming during continuous operation, and more of the motor drive force applied to the workpiece).

Hydrostatic Grinding Spindles

Radial Diameter: 24 mm

Maximum Speed: 35,000 RPM

Maximum Radial Load: 800 N

Radial Stiffness: 70 N/micro-m

Pump and Friction Power: 0.58 kW at 35,000 RPM

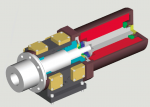

Hydrostatic Grinding Spindles with Integral Motors

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the

workpiece.

- Heat that is generated is moved immediately out of the spindle area with the oil and

cooled in the chiller.

- No vibration from roller bearings for extremely smooth operation.

- Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.

CBN Hydrostatic Grinding Spindle Systems

This is an example of a hydrostatic spindle designed for high speed grinding with CBN grinding wheels. The small bearing diameter in combination with high surface speed allows the use of CBN wheels even for undercuts in a camshaft application.

Hydrostatic Lathe Spindles

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the

workpiece. Heat that is generated is moved immediately out of the spindle area with the oil and cooled in the chiller.

- No vibration from roller bearings for extremely smooth operation.

- Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.