487.05C.000.000

5C Collet Runout Test Arbor

The C-style (Cataract) collet, invented in 1903 by Hardinge Brothers Inc. (now Hardinge Inc.), is an open international standard used by thousands of manufacturers for holding round, hex, and square stock. Originally sizes 3C, 4C, and 5C were available, however over time larger sizes (16C, 20C, and 25C ) are available with the most common size being the 5C.

Trivia: The C designation is named after the Niagara Falls "cataracts".

The TAC Rockford 5C Spindle Runout Test Bar is the definitive standard for verifying the accuracy of your 5C collet spindles. Designed for precision toolroom lathes, indexing heads, and grinding fixtures, this test bar provides an immediate, reliable baseline to diagnose spindle health, troubleshoot vibration issues, and certify machine alignment.

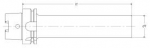

| Swiss Collet Type / Size | Length (L) | Diameter (D) | Part Number | |||||

|---|---|---|---|---|---|---|---|---|

| 5C | 200 mm | 32 mm | 487.05C.000.000 | |||||

| BS20 | 100 mm | 27 mm | 487.BS20.000.000 | |||||

| BS38 | 100 mm | 42 mm | 487.BS38.000.000 | |||||

| TF10 | 70 mm | 10 mm | 487.TF10.000.000 | |||||

| TF15 | 70 mm | 15 mm | 487.TF15.000.000 | |||||

| TF16 | 70 mm | 15 mm | 487.TF16.000.000 | |||||

| TF20 | 100 mm | 21 mm | 487.TF20.000.000 | |||||

| TF25 | 100 mm | 25 mm | 487.TF25.000.000 | |||||

| TF30 | 100 mm | 32 mm | 487.TF30.000.000 | |||||

| TF43 | 100 mm | 46 mm | 487.TF43.000.000 | |||||

| TF48 | 100 mm | 50 mm | 487.TF48.000.000 | |||||

| Other size or special configuration | Contact Us | 487.WHC.SP |

For more information regarding this item (5C Collet Runout Test Arbor) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

PSC / PSK Spindle Runout Test Arbors

Made to the ISO 26623 Standard. Maximum runout error 0.003mm / 3 micron / 0.00012”. A certificate of accuracy is included. Storage are cases not included.

TF and BS Swiss-Style Collet Runout Test Arbors

TAC Rockford workholding spindle runout test bars provide a definitive standard for verifying the accuracy of 5C, TF, BS, and other collet spindles.

Designed for precision collet chucks, Swiss-style lathes, indexing heads, and grinding fixtures, a runout test bar provides an immediate, reliable baseline to diagnose spindle health, troubleshoot vibration issues, and certify machine alignment.

<b>Additional product information can be found on the Details tab below.</b>

R8 Taper Spindle Runout Test Arbor

Standard R8 spindle runout test arbor with inch retention thread.

Runout <=0.003 micron (0.00012 inch)

Steep Taper Spindle Runout Test Arbors

-Maximum runout error 0.003mm / 3 micron / 0.00012 inch

-Cylindricity ≤ 0.002mm / 2 micron / 0.00008 inch

-Carrying cases are not included (see below for case options).

-A certificate of accuracy is included. Traceable certificates available; contact us for details.

-Contact us for other lengths, tapers, and other special requirements.

Spindle Runout Test Arbor Instructions

One of the leading causes of tool breakage, part finish issues, tolerance control, and machine registration issues is excessive spindle runout.

KM Spindle Runout Test Arbors

- Maximum runout error 0.003mm [0.00012 in.]

- Carrying cases are not included. Visit www.tac.us/runoutcases for available case styles (Data Sheet 465.006).

- A certificate of accuracy is included. Traceable certificates available; contact us for details.

- Contact us for other lengths, tapers, and other special requirements.

* ISO 26622 runout arbor tapers are compatible with machines using TS, XMZ (Mazak Integrex), and ATC. Flange may not be suitable for use with automatic tool changers.

A2 and D1 Flanged Lathe Spindle Runout Test Bars

Test arbor for mounting to turning-center and measuring run-out. Designed for A2-5, A2-6, D1-8 etc. lathe face mounting. Also available for flat 110 and 140 lathe face.

Extended drawbar clearance versions have additional depth at the taper needed for drawbar clearance on certain lathes.

HSK Spindle Runout Test Arbors

TAC Rockford's HSK Spindle Runout Test Arbors are the essential high-precision instrument for verifying the accuracy of your machine tool spindles. This critical gauge provides a fast, reliable, and definitive way to diagnose alignment and runout issues that directly impact part quality and tool life.

- Ultra-High Precision: Typically guaranteed radial runout of 0.003mm (3 microns / 0.0001") or better, ensuring the highest level of diagnostic accuracy.

- Manufactured from premium, hardened alloy steel and precision ground for stability and longevity.

- Each arbor is supplied with an individual Certificate.

- Contact us for other lengths, tapers, and other special requirements.

- Carrying cases are not included. Available case options listed below.

Carrying Cases for KM Runout Arbors

TAC Rockford runout arbor cases are specifically designed to protect your precision spindle runout test arbors. These cases feature high-density, custom-cut foam interiors that secure the arbors. They ensure your critical measurement tools are shielded from dirt, damage, and impact, maintaining their accuracy and readiness for preventative maintenance.

Carrying Cases for PSC Runout Arbors

TAC Rockford runout arbor cases are specifically designed to protect your precision spindle runout test arbors. These cases feature high-density, custom-cut foam interiors that secure the arbors. They ensure your critical measurement tools are shielded from dirt, damage, and impact, maintaining their accuracy and readiness for preventative maintenance.