451.CG0

Precision Granite Master Cylinders

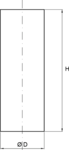

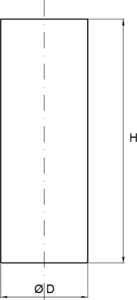

TAC Rockford Precision Granite Master Cylinders are the standard for verifying the perpendicularity, straightness, and runout of critical machine axes on high-precision machine tools and CMMs. Manufactured from select, high-density black granite, these cylinders offer unmatched dimensional stability and thermal inertness, making them essential for the most demanding metrology applications.

Standard sizes range from 200mm (7.87in) to 800mm (31.5") in height. Custom diameters, heights, and other special versions available upon request - contact our engineering team for specialized configurations.

| Cylinder | H (mm) | D (mm) | Perpendicularity (mm) | Cylindricity (mm) | Part Number | |||

|---|---|---|---|---|---|---|---|---|

| 200 x 70 | 200 | 70 | 0.002 | 0.002 | 451.CG0.200.070 | |||

| 300 x 80 | 300 | 80 | 0.003 | 0.003 | 451.CG0.300.080 | |||

| 400 x 100 | 400 | 100 | 0.004 | 0.004 | 451.CG0.400.100 | |||

| 500 x 120 | 500 | 120 | 0.005 | 0.005 | 451.CG0.500.120 | |||

| 800 x 160 | 800 | 160 | 0.006 | 0.006 | 451.CG0.800.160 |

Key Features & Benefits

Superior Accuracy: Laboratory Grade accuracy for the highest confidence in your measurements.

Thermal Stability: Granite's extremely low coefficient of thermal expansion minimizes dimensional changes due to temperature fluctuations, ensuring reliable readings in a controlled environment.

Exceptional Durability: The hard, dense granite resists wear, is non-magnetic, and is corrosion-proof, guaranteeing a long service life with minimal maintenance.

Precision Finish: Both the diameter and the ends are precision-lapped to achieve perfect parallelism, perpendicularity, and cylindricity, making them ideal for verifying the straightness and squareness of machine tool columns, calibrating the Z-axis of Coordinate Measuring Machines (CMMs) and checking the runout of rotary tables and spindles.

Traceability: Each cylinder is supplied with a calibration certificate to meet your strictest quality assurance requirements.

Applications:

- Coordinate Measuring Machines (CMMs)

- Machine Tool Calibration (Vertical Machining Centers)

- Precision Gauging and Layout

- Optical Inspection Systems

- Quality Control and Metrology Labs

For more information regarding this item (Precision Granite Master Cylinders) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Master Granite Setup Squares (90 degrees)

<b>This product has been replaced by:</b>

<a href="https://tacrockford.com/product/gauges/machine-center-dimensional/granite-squares/">Granite Square Series 451.2G0</a>

Granite block with two diamond-lapped measuring faces. Made in Germany to DIN 875 / 876 standard.

High Precision Steep Taper Gauge Masters

The High Precision Gauge Masters are made of a proprietary stabilized gauge material and are coated to resist corrosion. Actual dimensions are laser marked on the master. Included is a certificate with actual dimensions and a wooden storage case.

Zero Master Analog Setup Indicator

The Zero Master is the smallest 3D-Sensor worldwide. Usage, function and accuracy are equal to the Universal 3D-Sensor. The size of the Zero Master is adapted to small machines. The clamping shank has a diameter of 10 mm. Thus it can be also used on machines with ISO 30 or with small HSK spindles. The housing is shortened and does not protrude far out of the spindle so that even big work pieces can be measured. The Zero Master can be read with a small analog dial gauge.

Precision Measuring Cylinders

Hardened special steel. Machined base and jacket surface.

Workpiece Holding Clamping Systems

BERG-Spanntechnik offers an extensive range of power operated chucks and hydraulic cylinders which meet all the requirements of modern CNC lathes as there are effective clamping force, attainable numbers of rotation, and precision, as well as center hole width for bar stock.

High Precision HSK Gauge Masters

To check the extremely small tolerances required by the DIN and ISO

standards for HSK tool holders.