260.006

Rotary Unions for High Speed Applications and Dry Run

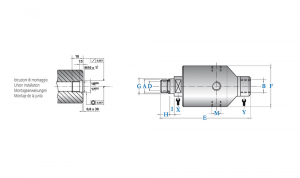

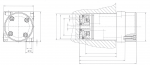

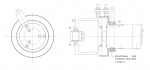

The unions for the models A and B have been designed for machine tool spindles rotating at high speed with fluid passing through or dry when needed. The seals, balanced and microlapped, remain always closed without problems both with fluid passing through (wet run) or without fluid (dry run).

![]() PDF Data Sheet: Rotary Unions for High Speed Applications and Dry Run (260.006)

PDF Data Sheet: Rotary Unions for High Speed Applications and Dry Run (260.006)

1 PASSAGE, SIZES 1/4" AND 3/8"

The unions for the models A and B have been designed for machine tool spindles rotating at high speed with fluid passing through or dry when needed. The seals, balanced and microlapped, remain always closed without problems both with fluid passing through (wet run) or without fluid (dry run).

For more information regarding this item (Rotary Unions for High Speed Applications and Dry Run) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Rotary Unions for High Speed Applications and High Pressure

The unions of model C are used in applications with high pressure and high rotation speed. A special double row bearing and the balanced sealing allow to operate at high pressure without any problem. Model D (heavy duty) seals in tungsten carbide to tungsten carbide, are microlapped for low friction. All the parts in contact with the fluid, made in stainless steel, allow to use the unions with many different fluids including water.

Rotary Unions for High Speed Applications

The unions of the models A and B are used for the passage of coolant through the machine tool spindles rotating at high speed. Well balanced seal assemblies model D, in tungsten carbide against tungsten carbide allow a low friction torque and long life even with a poor filtration of the coolant.

Rotary Transmission Leadthroughs HDF

Rotary transmission leadthroughs serve as a rear inter face for fluid transmission into the spindle. A hydromechanic clamping unit or integrated clamping cylinder can be actuated with the media oil, air and coolant. The transmission of oil and coolant is possible at rotational speed.

CBN Hydrostatic Grinding Spindle Systems

This is an example of a hydrostatic spindle designed for high speed grinding with CBN grinding wheels. The small bearing diameter in combination with high surface speed allows the use of CBN wheels even for undercuts in a camshaft application.

Hense Pneumatic Rotary Actuators

Hense rotary actuators provide an effective and economic solution for angular or straight motion when high force and torque is required.

Tube Couplers

Tube coupler for high-speed assembly of fiber glass strengthened plastic tubes in very high pressure ranges.

OHL and OHLK Tool Clamping Cylinders

Rotating hydraulic cylinders of the type OHLK..-1 and OHL..-1 are principally designed for actuating SK and HSK clamping sets. All coolant lubrication and compressed air supply variants are possible with a single device to meet the respective requirements. The control system is represented in the circuit diagram T 1345. Unlike spring actuated clamping and chucking systems, OHL(K) ..-1 hydraulic cylinders allow alteration of the clamping forces within wide limits. As the rotating cylinder is permanently connected to the spindle, no axial forces act upon the spindle bearings during tool release and ejection.

HSK Handbook

The HSK Handbook is recommended for end users involved in the implementation of HSK tooling, machine tool companies and distributors of CNC centers with HSK spindles, tooling departments responsible for HSK specifications, developers of HSK equipment and professionals looking for new tooling solutions for high speed/high rigidity machining.

Power Clamp Comfort Heat Shrink Systems

High performance shrink fit machine for all tools.

- With standard coil

- Rotary table with 3 stations

- With integrated contact cooling