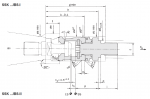

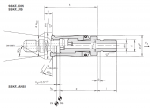

292-HHF

BERG EHHF and HHHF Handling Systems

The modular handling systems EHHF and HHHF are used as heavy duty grippers in various areas of machine tool and plant engineering.

![]() PDF Data Sheet: BERG EHHF and HHHF Handling Systems (292-HHF)

PDF Data Sheet: BERG EHHF and HHHF Handling Systems (292-HHF)

The modular handling systems EHHF and HHHF are used as heavy duty grippers in various areas of machine tool and plant engineering. These systems are suitable for use in applications requiring large gripping strokes under rough operating conditions and where high standards of operating safety are required.

For more information regarding this item (BERG EHHF and HHHF Handling Systems) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Tool Dynamic Economic Tool Balancing Systems

Long tools must be balanced in two planes in order to eliminate the couple unbalance. The handling is done by an integrated keyboard and screen, which is clearly designed. Furthermore the Economic Plus has an integrated drawer for accessories.

Manual Mechanical Self-locking Drawbar Style Clamping Systems

The manually actuated drawbar style die clamping system is designed for clamping dies of various widths on press slides and tables. The self-locking eccentric cam gear guarantees a simple handling with a maximum of safety.

Capto Clamping Systems

BERG Spanntechnik is a leading supplier of Capto grippers and clamping systems.

Power Clamp Nano Heat Shrink Systems

The all new Power Clamp Nano is your entry into the world of micro machining.

The new shrink fit machine was specifically developed for small interfaces, i.e. HSK 25, HSK 50 and SK/BT 30. The horizontal design ensures easy handling especially at tools with smaller diameters. By its modular system construction Power Clamp Nano fulfills the various customer requirements very well.

Steep Taper Grippers SSK-JBS

SSK gripper are primarily designed for drawing in and ejecting steep taper tooling provided with retention knobs internationally standardized as per DIN, ANSI, MAS, JIS and ISO which allow fast automatic tool changes. SSK grippers are not only suitable for clamping tools, but also workpieces or workpiece holders and pallets on machining centers, milling machines, boring machines, grinding centers, special purpose machines, and handling systems.

Overview: Clamping Systems with AS-Interface

The BERG AS-Interface clamping and chucking systems are intended for clamping various tools/dies on press slides and black holders, and for sliding table clamping and gripper rail couplings on multiple die presses. They are used on new machines and for retrofitting automatic clamping systems in existing press lines.

Steep Taper Grippers SSKF

With an easy-to-machine spindle contour, BERG Spanntechnik SSKF gripper is designed for cost-sensitive applications.

Manually-Movable Clamping Systems

The manually actuated die clamping system PSP.AM is designed for clamping dies of various widths on on press slides and tables. The selflocking eccentric cam gear guarantees a simple handling with a maximum of reliability.

Workpiece Holding Clamping Systems

BERG-Spanntechnik offers an extensive range of power operated chucks and hydraulic cylinders which meet all the requirements of modern CNC lathes as there are effective clamping force, attainable numbers of rotation, and precision, as well as center hole width for bar stock.