101.002

HSK Standards

Hollow Taper Shank Technical Standards

Contact us for HSK standards documentation

Hollow Taper Shank Type A

For use with machining centers, milling machines, special-purpose machines with automatic tool changing. Hollow Taper Shanks for Automatic Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 with Gripper Groove.

Hollow Taper Shank Type B

For use with machining centers, milling machines for heavy-duty machining, lathes. Hollow Taper Shanks for Automatic Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 with Gripper Groove.

Hollow Taper Shank Type C

Preferably for use with spindles in transfer lines and special-purpose machines without automatic tool changing, stub spindles, extensions or reducers. Hollow Taper Shanks for Manual Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 without Gripper Groove.

Hollow Taper Shank Type D

For use in all areas which require even better support with manual tool changing via a large contact face. Hollow Taper Shanks for Manual Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 without Gripper Groove.

Hollow Taper Shank Type E

For use with high-frequency spindles and wood working machines. Hollow Taper Shanks for High-Speed Cutting (HSC) acc. to the Pre-Standard DIN 69 893 Part 5 and 6 with Gripper Groove.

Hollow Taper Shank Type F

With enlarged flange diameter. Hollow Taper Shanks for High-Speed Cutting (HSC) acc. to the Pre-Standard DIN 69 893 Part 5 and 6 with Gripper Groove.

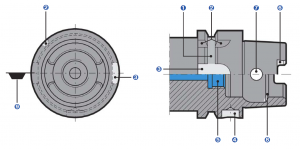

Term definitions of HSK-A interface for automatic tooling systems(1) Gripper groove: circular groove

(2) Index notch: sickle-shaped notch across gripper groove

(3) Keyway on collar: index notch or for attachment in tool magazine or grippers. HSK-B/D also provides form closed torque transmission to spindle.

(4) Coding/identification: bore in collar for attachment of identification system (coding chip)

(5) Thread for coolant: for attachment of coolant supply set

(6) Keyway on taper shank: form closed torque transmission to spindle

(7) Radial bore in taper shank: necessary for manual clamping systems

(8) Clamping shoulder: circular chamfer for drawing in the tool

(9) Position of the tool edge of single-edged tools

HSK Tool Holders DIN 69893The hollow taper shank (HSK) has prevailed since its standardization as an interface between machine and tool.

HSK benefits to the user include: • High static and dynamic rigidity

• High precision axial and radial reproducibility

• High tool change accuracy and repeatability

• High speed machining performance

• Short tool changing times

• Coding and identification

• Coolant feed

Balancing recommendations and RPM limitsBecause the rotational speed is the largest influencing factor together with the limits regarding the spindle or spindle bearing interface, the following RPM limits for HSK interfaces have been recommended as guidelines within the HSK standards:

HSK-A/C 32 to 30,000 rev./min

HSK-A/C 40 to 30,000 rev./min

HSK-A/C 50 to 30,000 rev./min

HSK-A/C 63 to 25,000 rev./min

HSK-A/C 80 to 20,000 rev./min

HSK-A/C 100 to 16,000 rev./min

Depending on the tool, it may be necessary to balance both the tool holder and tool when applying the maximum RPM. Exact limits can only be determined if machine and spindle manufacturers are taken into consideration and it is possible to define tools and projecting lengths.

For more information regarding this item (HSK Standards) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Hollow Taper Shank Type A

For use with machining centers, milling machines, special-purpose machines with automatic tool changing. Hollow Taper Shanks for Automatic Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 with Gripper Groove.

Hollow Taper Shank Type B

For use with machining centers, milling machines for heavy-duty machining, lathes. Hollow Taper Shanks for Automatic Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 with Gripper Groove.

Hollow Taper Shank Type C

Preferably for use with spindles in transfer lines and special-purpose machines without automatic tool changing, stub spindles, extensions or reducers. Hollow Taper Shanks for Manual Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 without Gripper Groove.

Hollow Taper Shank Type D

For use in all areas which require even better support with manual tool changing via a large contact face. Hollow Taper Shanks for Manual Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 without Gripper Groove.

Hollow Taper Shank Type E

For use with high-frequency spindles and wood working machines. Hollow Taper Shanks for High-Speed Cutting (HSC) acc. to the Pre-Standard DIN 69 893 Part 5 and 6 with Gripper Groove.

Hollow Taper Shank Type F

With enlarged flange diameter. Hollow Taper Shanks for High-Speed Cutting (HSC) acc. to the Pre-Standard DIN 69 893 Part 5 and 6 with Gripper Groove.