Search Results for "BERG"

81 item(s) found

Stationary Clamping Systems

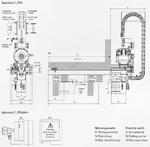

The hydraulic die clamping system, PSP...HB, is designed to automatically clamp tools at the press slide or on the table. In the "Unclamped" position, the tensioning rod is completely retracted into the clamping element and initially moved out of the clamping element when pressure is applied.

Manually-Movable Clamping Systems

The manually actuated die clamping system PSP.AM is designed for clamping dies of various widths on on press slides and tables. The selflocking eccentric cam gear guarantees a simple handling with a maximum of reliability.

Transfer Rail Couplings

The mechanical self-locking Berg gripper rail coupling GSM is designed for manual coupling of gripper rails on transfer presses. A vertical lift-out stroke is required for changing the tool.

Workpiece Holding Clamping Systems

BERG-Spanntechnik offers an extensive range of power operated chucks and hydraulic cylinders which meet all the requirements of modern CNC lathes as there are effective clamping force, attainable numbers of rotation, and precision, as well as center hole width for bar stock.

EHHF and HHHF Handling Systems

The modular handling systems EHHF and HHHF are used as heavy duty grippers in various areas of machine tool and plant engineering.

Pallet Holding Force Gauges

Clamping force measuring gauges for pallets are intended to quickly measure the holding force of individual clamping heads.

Pallet clamping adapters are per-application based, and are fitted according to the specifications of the customer's pallet system.

Clamping adapters can be or have been provided for various pallet systems: BERG, Rohm, Mazak, OTT, Schunk, Erowa, and others.

NSM-PV Zero Point Clamping System

NSM PV zero point clamping heads are used for fixture and pallet clamping on machine tools. With the clamping heads and the associated clamping bolts provide for the highest levels of clamping position repeatability. Due to the mechanical integrated booster and lock, the clamping head is also suitable for pallets, tombstones, pivot tables and vertical applications. The chuck can be configured as double, 4-fold and custom multi-application.

NAB Pull Studs

Pull studs are the interface between devices, pallets and the clamping systems of the machine tool. For applications with two, four or more clamping heads, solid bolts are used for center position, sword bolts are used to determine the angled position and retaining bolts are exclusively used for vertical positioning. Versions are available for both front and rear installation.

Parallel to the applications of the BERG clamping heads with support cone, screw-in bolts are available as solid bolts and retaining bolts with screw thread. These are used for very high drawing-in forces and maximum stability in a minimum amount of space.

Automatic Hydro-mechanical Self-locking C-clamping Systems

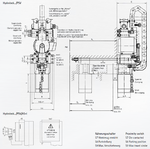

The C-clamping hydromechanical self-locking (hydrolock) die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the parking position and the respective die. Clamping and unclamping are performed by a hydromechanical self-locking clamping gear. Hydraulic pressure is at a maximum of 90 bar.

Automatic Hydro-mechanical Self-locking Drawbar Style Clamping Systems

The drawbar style hydromechanical (hydrolock) self-locking die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the parking position and the respective die. Clamping and unclamping are performed by a hydromechanical self-locking clamping gear. Hydraulic pressure is at a maximum 90 bar.

Automatic Electromechanical Bellcrank Lever Style Clamping Systems

Electromechanical clamp for die clamping on press slides. The clamp automatically travels between the parking position and the actual die, guided by the T-slot of the slide. The bell-crank lever covers a wider clamping range.

Automatic Electromechanical Wedgebar Style Clamping Systems

Electromechanical clamp for die clamping on press slides. The clamp automatically travels between the parking position and the actual die, guided by the T-slot of the slide. In parking position, the clamp is safely locked by the wedge jaw.

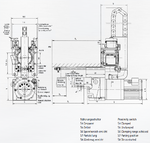

Automatic Electromechanical Drawbar Style Clamping Systems

The electro-mechanical self-locking drawbar style clamping system is designed for quick clamping dies of different widths with clamping slot on press slides.

The clamping systems are controlled de-centrally and individually in each clamping system. Each local clamp control system communicates with the pressing machine control system. The clamping actuator automatically moves into the T-slot of the press slide between the parking position and the respective die. The electro-mechanical clamping system clamps the die and switches off automatically on reaching the clamping force.

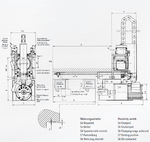

Automatic Hydraulic Drawbar Style Clamping Systems

The hydraulic die clamping system with drawbar style clamping is designed for clamping dies of different widths on press slides. The clamping actuator moves automatically into the T-slot of the press slide between the parking position and the respective die. The clamping element can clamp different clamping rim heights due to the long clamping stroke of the double acting cylinder. Hydraulic pressure is at a maximum 400 bar.

Automatic Hydraulic C-clamping Systems

The C-clamping hydraulic die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the park position and the respective die. Hydraulic pressure is at a maximum 400 bar

Konenberg Replacement Parts Service

European or Asian replacement part service for Konenberg. Whether for hard to get or find parts, saving time and money on overseas shipping, Transatlantic Connection handles the rest. We have purchased and/or quoted components from Konenberg in the past with arrangements to our customers.