240.352

Application: Hydrostatic Rotary Tables

The world's largest gear and profile grinding machines use hydrostatic bearings.

![]() PDF Data Sheet: Application: Hydrostatic Rotary Tables (240.352)

PDF Data Sheet: Application: Hydrostatic Rotary Tables (240.352)

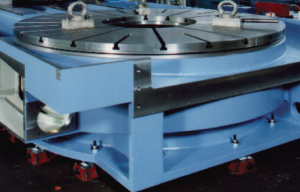

Effortlessly Moving a 88,000 Pound Machine TableThe world's largest gear and profile grinding machines use hydrostatic bearings.

• Gleason-Pfauter of Ludwigsburg, Germany built the world’s largest machine for gear grinding. One of the engineering highlights of this machine is the use of a hydrostatic bearing system for the rotating table. This table design makes it possible to very

accurately machine gears up to 40 metric tons in weight.

The new machine can grind hardened gears with a diameter of 3 meters, a width of 2 meters, and a weight of 40,000 kg with a guaranteed accuracy of 4 per DIN Specification 3962. The maximum profile depth is 100 mm. The grinding wheel is powered by a 50 kW / 75 hp drive motor. The machine is designed to manufacture precise gears for steel mills and other large gear applications.

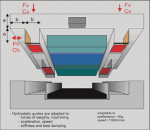

The high table load and machining forces are not a problem for the hydrostatic bearings. Dampening of the hydrostatic system is 10 to 100 times better than with roller bearings, resulting in better surface quality of the gear. The round table floats – independent of speed – on a number of 20 micron hydrostatic bearing pockets. The end result is a totally wear-resistant system with very high stiffness. The accuracy of the machine can be expected to be unchanged over many years of operation since no wear takes place. With the use of a HYPROSTATIK PM controller system for the oil fl ow, the

hydrostatic pockets are so stiff that a 40 ton gear load will change the bearing gap by only a few microns. The mechanical PM fl ow controller employs a unique and patented design and is manufactured by HYPROSTATIK of Goeppingen, Germany.

The achievable roundness accuracy of the rotating table is much better than that of tables with comparable roller type bearings. At low RPM, friction is virtually nonexistent. In fact, friction is so low that one person can easily move the table with a 40 ton workpiece on it by hand. This low friction allows the table to be positioned second angle movements without backlash or high initial friction. Such slow and accurate positioning is only possible because of the hydrostatic bearing.

The typical oscillating motions used during gear grinding cause wear when using ballscrews. This results in loss of accuracy and can lead to failures over time. When using hydrostatic guide ways and hydrostatic lead screws, oscillating machine motion does not cause wear or loss of accuracy.

In addition, to further reduce friction and wear, hydrostatic bearings from HYPROSTATIK are installed on the table drive worm gear spindle and on the ways for the machine column.

The engineering calculations required for implementing the hydrostatic system were made by HYPROSTATIK. Since the hydrostatic pockets are machined directly into the frame of the machine and the table sits directly on the frame, there is no need for

additional components between the table and machine frame. Hydrostatic bearings not only improve the machine’s accuracy but also reduce the cost!

Hydrostatic systems that improve machine accuracy can also be used on machining centers, grinding machines, lathes, and spindles for rotating tables, guide ways, bearings, and threaded spindles. For more information, contact Transatlantic Connection, Inc. – US Representative for Hyprostatik.

For more information regarding this item (Application: Hydrostatic Rotary Tables) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

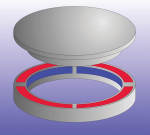

Hydrostatic Rotary Tables

Application example of a glass grinding machine used at Zeiss.

CBN Hydrostatic Grinding Spindle Systems

This is an example of a hydrostatic spindle designed for high speed grinding with CBN grinding wheels. The small bearing diameter in combination with high surface speed allows the use of CBN wheels even for undercuts in a camshaft application.

Hydrostatic Application Worksheet

Download the PDF data sheet for the Hydrostatic Application Worksheet

Hydrostatic Leadscrews

- Speed comparable to a linear motor

- Very low friction when machining, virtually frictionless

during positioning

- Steps in the 0.1 micron range are possible

- No backlash when reversing direction

Rotary Transmission Leadthroughs HDF

Rotary transmission leadthroughs serve as a rear inter face for fluid transmission into the spindle. A hydromechanic clamping unit or integrated clamping cylinder can be actuated with the media oil, air and coolant. The transmission of oil and coolant is possible at rotational speed.

Hense Pneumatic Rotary Actuators

Hense rotary actuators provide an effective and economic solution for angular or straight motion when high force and torque is required.

NSM-PV Zero Point Clamping System

NSM PV zero point clamping heads are used for fixture and pallet clamping on machine tools. With the clamping heads and the associated clamping bolts provide for the highest levels of clamping position repeatability. Due to the mechanical integrated booster and lock, the clamping head is also suitable for pallets, tombstones, pivot tables and vertical applications. The chuck can be configured as double, 4-fold and custom multi-application.

Hydrostatic Linear Motor Guide

The PM Flow Controller makes it possible for machine builders to easily integrate custom hydrostatic systems into both new and existing machines.

SPM-HV Pallet Clamping Heads

SPM-HV series pallet clamping heads are used for pallet clamping on single or double axis indexing tables. With the clamping heads and matching tapered rings, maximum workpiece position repeatability and precision is possible.