495.800

ForceCheck Chuck Force Sensor Extensions and Accessories

Accessories for the chuck force include a variety of types of rest pads and extensions to match the gripping jaws on a turning-center/chuck.

![]() PDF Data Sheet: ForceCheck Chuck Force Sensor Extensions and Accessories (495.800)

PDF Data Sheet: ForceCheck Chuck Force Sensor Extensions and Accessories (495.800)

Accessories for the chuck force include a variety of types of rest pads and extensions to match the gripping jaws on a turning-center/chuck.

Rest Pads • Flat rest pads are made with hardened steel for durability and repeatability

• "Radiused" rest pads are designed for better centering on the chuck jaws during force measurement – recommended to also use with an insertion depth control ring

• Special diameter rest pads are where the customer specifies the overall clamping diameter and number of jaws when ordering

Insertion Depth Control RingUnique to ForceCheck chuck gauges, this is a special accessory that prevents the force sensor from slipping or being misaligned during measurement. This can prevent damage to unit if the sensor is not properly centered inside the chuck (where the chuck jaws are gripping the rest pads at precisely the same instance), or the chuck force gauge is positioned at a bad angle not allowing each sensor gripping pad to be parallel and flush with the chuck jaws.

The insertion depth ring solves alignment issues along with providing a continuous force reading after each use – it ensures the chuck force sensor is correctly positioned every time.

Support RingPart of an extension rest pad set for larger chuck clamping diameters, the support ring adds stability and proper centering of the rest pads.

For more information regarding this item (ForceCheck Chuck Force Sensor Extensions and Accessories) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

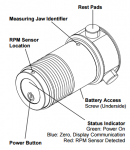

Wireless Chuck Force Sensor Manual

The ForceCheck chuck force gauge is designed to measure the clamping forces created by a chuck. The wireless sensor can be used for either static (non-rotating) or dynamic (rotating) measurements. When rotating, the sensor can also measure RPM (Revolutions Per Minute).

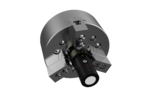

Large Diameter VTL Chuck Force Gauges

Measure clamping force on 12+ inch diameter chucks. Available as wired or wireless sensor unit. Base set is separate which includes wired or wireless read-out display, custom case, and accessories for the sensor.

Chuck Force Gauges - Wired

Designed to quickly check the holding force on a chuck or turning-center. The wired chuck force gauge can be customized for any diameter.

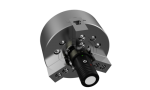

Wireless Chuck Force Sensor Sets

Suitable for measuring RPM and force at the same time. These are complete sets that include sensor, standard rest pads, RPM magnetic wand, display, and padded carrying case. Contact us for custom sizes and multi-adapter sets.

Wireless Chuck Force Gauges

The ForceCheck wireless chuck force gauge is designed to quickly and accurately measure holding force and speed on chucks. Verifying chuck holding force allows manufacturers to improve the repeatability of a manufacturing process by checking actual holding force under dynamic (rotating) conditions, as well as perform critical preventative maintenance checks. Contact us for other clamping diameters and extension rings, as well as 4+ jaw chucks.

ForceCheck Hydraulic Tool Holder Force Gauges

Hydraulic tool holders are an excellent ultra-low option with added benefits such as vibration damping and ease of use. One of the major challenges with hydraulic holders is determining if they are still functioning correctly over time. Failure of the hydaulic holding mechanism is often not apparent until cutter slippage occurs, potentially causing damage to both the holder and a scrapped workpiece.

ForceCheck hydraulic tool holder force gauges provide a quick and reliable way to verify a tool holder is still operating correctly. The sensor measures the force at the center of the hydraulic sleeve.

Using the gauge is as easy as inserting the sensor in the hydraulic holder. Once the actuation piston compresses the hydraulic fluid in the expansion sleeve, the resulting force is shown on a handheld digital display. The measured force can be compared to a new or known-good hydraulic tool holder.

Chuck Force Interpretation: Jaw Force vs. Total Gripping Force

Understanding the data on your ForceCheck display is the first step toward ensuring a safe and repeatable machining process. We often receive questions regarding whether the number on the screen represents the entire capability of the chuck or just a portion of it. To clarify, the ForceCheck gauge measures the radial force of a single jaw, which is only one component of the total holding power. Because a chuck relies on multiple jaws working in unison to secure a workpiece, calculating the actual clamping capacity requires a simple conversion based on your specific chuck configuration.

The “Total Gripping Force” (F<sub>total</sub>) is defined as the arithmetic sum of the individual radial forces exerted by each jaw.

The force value shown on the ForceCheck display represents the measured radial force of a single jaw (F<sub>jaw</sub>) at the measurement diameter. This is different than the total gripping force of the chuck.

<strong>Calculating Total Gripping Force</strong>

Since the jaws move simultaneously and are driven by the same mechanism (usually a scroll plate or a hydraulic wedge), under ideal conditions the force is distributed equally among them.

F<sub>total</sub> = n × F<sub>jaw</sub>

Where:

-F<sub>total </sub>= Total gripping force

-n = Number of jaws

-F<sub>jaw</sub> = Force measured at a single jaw (value shown on ForceCheck display)

Examples:

3-jaw chuck

-Displayed Force Fjaw = 10 kN

-Total Gripping Force F<sub>total</sub> = 3 × 10 kN = 30 kN

5-jaw chuck

-Displayed force = 10 kN

-Total gripping force = 5 × 10 kN = 50 kN

<strong>Important Distinction: Force vs. Pressure</strong>

It is a common point of confusion whether the forces “cancel out” since they are opposing each other.

-<strong>Net Force on the Part:</strong> The vector sum of forces acting on a properly centered part is 0 kN. This is why the part remains stationary in the chuck.

-<strong>Gripping/Clamping Force:</strong> In terms of holding power and part deformation, we use the sum of the magnitudes. This total force determines how much friction is generated to resist cutting forces and how much the part might “crush” or distort.

<strong>Factors That May Change This Value</strong>

Your “real world” force may differ based on these conditions:

-<strong>Dynamic Loss (Centrifugal Force):</strong> If the chuck is spinning, the jaws want to fly outward due to centrifugal force. This reduces the actual gripping force. At high RPMs, the force when compared to a static condition could drop significantly.

-<strong>Friction and Lubrication:</strong> If you are measuring the force at the sensor but the other jaws are poorly lubricated, they may not actually be producing the same force.

-<strong>Part Geometry:</strong> If the part is not perfectly round or the jaws are not making full contact, the force distribution might become uneven, though the total input force from the chuck mechanism remains the same.

ForceCheck Workholding Collet Force Gauge

ForceCheck collet force gauges provide a quick and easy way to check force on collet workholding systems.

Applications for ForceCheck workholding collet force gauges include:

-Comparison of holding force between machines, allowing for consistent and repeatable production results regardless of mechanism (manual, hydraulic, or pneumatic)

-Periodic verification to assess if preventive maintenance is needed

-Establish correct holding force for running a particular part or job

-Determine optimal holding force for thin-wall, rings, and other parts sensitive to damage or distortion when machining

A sensor is needed for each diameter to be measured. A ForceCheck base set with display is needed to display results (order separately).

Sensors are also available in low-force versions. Contact us for further information.

Wireless Sensor Operating Instructions

The ForceCheck wireless sensor measures the clamping force of power drawbars on machining centers. Designed for use with the ForceCheck Wireless Display (461.110).

Download or print PDF data sheet for instruction manual.