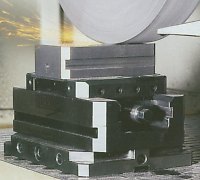

The PositiveLock system CenterCompact vises are ideally suited to 3-D machining because of 5-side part access and the compact size. Click for larger image.

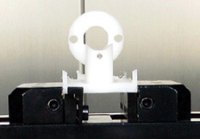

A PositiveLock system CenterCompact vise mounted on a QuickPoint base plate is a very secure way to hold a workpiece, as is shown in this demonstration. Using the QuickPoint base plate, the workpiece can also easily be turned 90 degrees for additional operations. Click for a larger image.

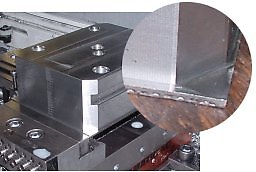

Multiple Center-Compact vises and QuickPoint base plates can be used together for unusually large workpieces. In this case, a large hot-rolled barstock workpiece is held with only 0.16 in. (4 mm) of material in the vise jaws. Click for a larger image.

Plates for custom fixtures are available for QuickPoint base plates, such as this chuck. Using a QuickPoint base plate, fixtures can be changed on a machine in seconds. The fixture will always be located in a precise location, eliminating the need to re-set a program home position every time the fixture is installed. Click for a larger image.

In this example, a thread lock is completely machined, except for a 0.08 inch (2 mm) clamping surface. After the first operation, the part is turned over and the excess material is removed. Click for a larger image.

The PositiveLock system provides for a totally new way to make round parts. In this example, a round part is completely machined from all sides by indexing it 90 degrees using the QuickPoint vertical stand. The remaining 0.08 inch (2 mm) of material is turned off on a turning center. Click for a larger image.

Using a CenterCompact vise and QuickPoint base plates, a workpiece can be moved from one machine to another without changing the workpiece home. Click for a larger image.

The low clamping force needed to hold parts with the PositiveLock system allows thin and flexible materials to be held. In this application, a block of Teflon is machined to produce the part. Click for a larger image.

In machining CenterCompact vise bodies, only 0.08 (2 mm) of the raw material is held in PositiveLock vise jaws. The body is completely machined on 5 sides, and then conventionally clamped to remove the extra 0.08 of material.

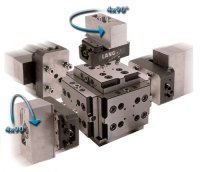

A machine with a QuickPoint cube installed offers an easy way to gain access to 5 sides of a workpiece. For parts requiring machining operations on all sides, workpieces can be rotated through the 5 stations, allowing 5 parts (one in each orientation) to be machined in one cycle. Click for a larger image.

This plastic cover is held by only 3 mm. Click for a larger image.

The compact size of CenterCompact vises allows more workpieces to fit in a machine. In this example, round QuickPoint base plates are used on a 3-station trunnion. Click for a larger image.

The small size of CenterCompact vises allows more workpieces to fit in a machine. The system is ideal for use with other fixturing devices such as tombstones. Click for a larger image.

The small size of CenterCompact vise is ideally suited for automated workpiece loading. Diverse workpieces can stay clamped in standardized and automatable units as they progress from machine to machine. Click for a larger image.

CenterCompact vises and QuickPoint base plates used on a rotary table. Click for a larger image.