694.1745

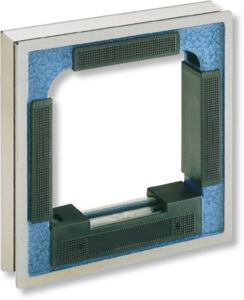

Machinist Precision Square Levels

Standard square frame engineer's level per DIN 877

Special cast-iron frame with insulated pads. 4 measuring faces, 3 with V grooves. Longitudinal and lateral vials. Carrying case included. Made in Germany. Additional sensitivities available: 0.3, 0.1, 0.02, and 0.01 mm/m (contact us for further information). Levels for large shaft-diameter or with magnetic faces available on request.

| Size (mm) | Width (mm) | Sensitivity (mm/m) | Part Number | |||||

|---|---|---|---|---|---|---|---|---|

| 100x100 | 27 | 0.04 | 694.1747.101 | |||||

| 150x150 | 35 | 0.04 | 694.1747.102 | |||||

| 200x200 | 40 | 0.04 | 694.1747.103 | |||||

| 300x300 | 55 | 0.04 | 694.1747.104 |

Special cast-iron frame with insulated pads. 4 measuring faces, 3 with V grooves. Longitudinal and lateral vials. Carrying case included. Made in Germany.

Additional sensitivities available: 0.3, 0.1, 0.02, and 0.01 mm/m. Contact us for further information.

Levels for large shaft-diameter or with magnetic faces available on request.

For more information regarding this item (Machinist Precision Square Levels) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Machinist Precision Horizontal Levels

Special cast-iron base with insulated pads. 4 measuring faces, 3 with V grooves. Longitudinal and lateral vials. Carrying case included. Made in Germany.

Additional sensitivities available: 0.3, 0.1, 0.02, and 0.01 mm/m (contact us for further information).

Levels for large shaft-diameter or with magnetic faces available on request.

HSK-C Weldon and Whistle-Notch Holders

The hole diameter and circular deviation tolerances have been significantly tightened up compared with DIN 1835 in order to achieve the highest levels of machining precision. Available for HSK-C 32, 40, 50, 63.

HSK-E Weldon Holders

The hole diameter and circular deviation tolerances have been significantly tightened up compared with DIN 1835 in order to achieve the highest levels of machining precision. Available to HSK-E 25, 32, 40, 50, 63.

Square Springs

We are your specialists in the manufacturing of square springs for industrial use. Our standard springs are made of 1.4310 material with a wire thickness of 1.0 mm. Other materials and thickness values are available at request.

HSK-A Whistle-Notch Holders

For end mills with shank DIN 1835-B and / or DIN 1835-E. The hole diameter and circular deviation tolerances have been significantly tightened up compared with DIN 1835 in order to achieve the highest levels of machining precision. Balanced according to ISO 1940-1 up to 10,000 rpm. Available for HSK-A 32, 40, 50, 63, 80, 100.

HSK-A Weldon Holders

For end mills with shank DIN 1835-B

- DIN 6535 HB. The hole diameter and circular deviation tolerances have been significantly tightened up compared with DIN 1835 in order to achieve the highest levels of machining precision. Balanced according to ISO 1940-1 up to 10,000 rpm. Available for HSK-A 32, 40, 50, 63, 80, 100.

Precision Measuring Cylinders

Hardened special steel. Machined base and jacket surface.

Tension and Torsion Springs

We are able to offer our customers tension, torsion and individual form springs made of round, square or flat wire as well as of strip steel for all kinds of applications.

PSC / PSK Taper Standard Ball-End Runout Test Arbors

Precision Spindle Analysis for 5-Axis Machining

Ensure the highest levels of accuracy and performance from your machine tools with the TAC Rockford PSC (Polygonal-Shank Taper) Ball End Test Arbor. Specifically designed for the verification of 5-axis machining centers, this precision instrument is essential for maintaining spindle health and positioning integrity.

Key Features:

PSC Taper Standard: Built to the ISO 26623 Standard for seamless integration and accurate seating in your PSC spindle.

5-Axis Positioning Accuracy: Primarily used for precisely checking the positioning accuracy of 5-axis spindles, especially the Rotary Tool Center Point (RTCP).

Spindle Runout Verification: Functions as a highly accurate runout test arbor to quickly and easily check that your machine spindle is running true.

Versatile Ball End: The precision ball end is ideal for establishing a consistent and repeatable touch-off point from the spindle face, a critical step for machine setup and calibration. It also provides a shorter alternative to standard runout bars when required.

Precision and Reliability: TAC Rockford's commitment to quality ensures a reliable instrument for periodic performance checks, verification after a machine crash, or installation/relocation.

Included Certificate of Accuracy: Each arbor comes with a certificate of accuracy to confirm its adherence to strict quality standards.