293-PSP-HB

BERG Stationary Hydraulic Pull-back Rotational Style Clamping Systems

Quick die changing system with pull-back rotational style clamping

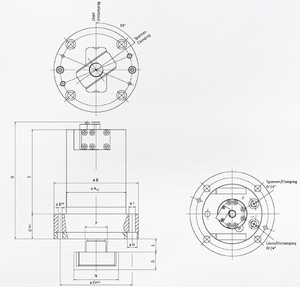

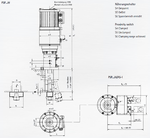

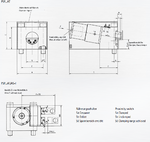

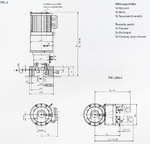

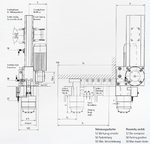

The hydraulic die clamping system with pull-back rotational style clamping is designed to clamp tools automatically at the press slide or on the table.

![]() PDF Data Sheet: BERG Stationary Hydraulic Pull-back Rotational Style Clamping Systems (293-PSP-HB)

PDF Data Sheet: BERG Stationary Hydraulic Pull-back Rotational Style Clamping Systems (293-PSP-HB)

The hydraulic die clamping system with pull-back rotational style clamping is designed to clamp tools automatically at the press slide or on the table.

In the unclamped position, the tensioning rod is completely retracted into the clamping element and initially moved out of the clamping element when pressure is applied. In the maximum extended position, the hammer head automatically rotates into its clamping position (55 degrees) and executes the clamping stroke while being retracted. When the hammer head makes contact with the clamping surface, clamping pressure and thus clamping force is built up. For unclamping, the sequence is executed in the reverse order until the hammer head is completely retracted into the clamping element again and the tool can be changed.

For more information regarding this item (BERG Stationary Hydraulic Pull-back Rotational Style Clamping Systems) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

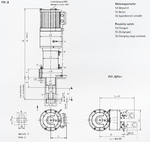

Stationary Electromechanical Pull-back Rotational Style Clamping Systems

Electromechanical pull-back rotational clamp for die clamping on slides and for clamping of moving bolsters. When unclamping the draw bar rotates 90 degrees and withdraws by 120 mm max.

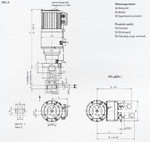

Stationary Electromechanical Rotational Style Clamping Systems

Electromechanical rotational-style clamp for die clamping on slides and blank-holders. When unclamping, the draw bar rotates 90 degrees.

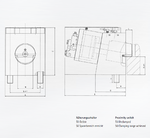

Stationary Hydraulic Wedgebar Style Clamping Systems

The hydromechanical wedge bar style clamping system is designed for clamping moving bolsters. The clamping slide generating the clamping force moves back into the housing after release.

Stationary Clamping Systems

The hydraulic die clamping system, PSP...HB, is designed to automatically clamp tools at the press slide or on the table. In the "Unclamped" position, the tensioning rod is completely retracted into the clamping element and initially moved out of the clamping element when pressure is applied.

Stationary Hydraulic Self-locking Swing-out Style Clamping Systems

Hydraulic, self-locking stationary swing-out style clamp for die clamping on slides and blackholders. When unclamping the draw bar swings out up to 15 degrees max.

Stationary Electromechanical Swing-out Style Clamping Systems

Electromechanical swing-out style clamp for die clamping on slides and blank-holders. When unclamping the draw-bar swings out up to 15 degrees maximum.

Stationary Electromechanical Moving Bolster Clamp Wedgebar Style Clamping Systems

Electromechanical wedgebar style clamp for clamping moving bolsters. When unclamping, the clamping wedge withdraws into the clamp body.

Stationary Electromechanical Gripper Style Clamping Systems

Electromechanical gripper style clamp for die clamping on sides. When unclamping the collet opens in order to disengage the draw bolt of the die.

Automatic Hydraulic Push Drive Chain-type Clamping Systems

The push drive chain-type hydraulic die clamping system is designed for clamping dies of various widths on press slides. The push-pull chain actuator moves automatically in the T-slot of the press slide between the parking position and the respective die. Hydraulic pressure is at a maximum 400 bar. The push-pull chain actuator can be used alternative to the PSV/PLV clamping actuator for every BERG press clamping system.