350.120

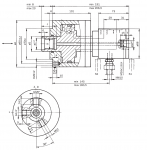

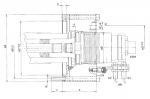

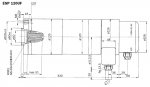

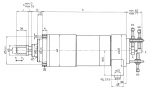

Hense Hydraulic Rotary Actuators

For more information regarding this item (Hense Hydraulic Rotary Actuators) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Hense Pneumatic Rotary Actuators

Hense rotary actuators provide an effective and economic solution for angular or straight motion when high force and torque is required.

Rotary Transmission Leadthroughs HDF

Rotary transmission leadthroughs serve as a rear inter face for fluid transmission into the spindle. A hydromechanic clamping unit or integrated clamping cylinder can be actuated with the media oil, air and coolant. The transmission of oil and coolant is possible at rotational speed.

OSKL Tool Clamping Cylinders

OSKL rotating hydraulic cylinders are primarily designed for actuating SSK gripper, but are also suitable for operating other clamping and chucking systems.

HLZ Tool Clamping Cylinders

HLZ hydraulic cylinders, in conjunction with spring actuated tool clamping and chucking devices, are intended for release and ejection of steep taper tooling and for stationary mounting.

ESP UF Tool Clamping Cylinders

ESP UF electro-mechanical actuators are intended for the power actuated clamping and release of steep taper tooling on milling and boring machines on which the tool change is performed manually. They are firmly connected by way of appropriate connection pieces to the workspindle which has a maximum rotational speed of 4000 rpm. The electrical control can be per formed both manually and automatically.

ForceCheck Hydraulic Tool Holder Force Gauges

Hydraulic tool holders are an excellent ultra-low option with added benefits such as vibration damping and ease of use. One of the major challenges with hydraulic holders is determining if they are still functioning correctly over time. Failure of the hydaulic holding mechanism is often not apparent until cutter slippage occurs, potentially causing damage to both the holder and a scrapped workpiece.

ForceCheck hydraulic tool holder force gauges provide a quick and reliable way to verify a tool holder is still operating correctly. The sensor measures the force at the center of the hydraulic sleeve.

Using the gauge is as easy as inserting the sensor in the hydraulic holder. Once the actuation piston compresses the hydraulic fluid in the expansion sleeve, the resulting force is shown on a handheld digital display. The measured force can be compared to a new or known-good hydraulic tool holder.

ESK Tool Clamping Cylinders

The electro-mechanical actuator is specifically designed for actuating the SSK gripper. This device generates both the clamping force, adjustable throughout a wide range, as well as the higher release force required for tool ejection. Up to a spindle rotational speed of 4000 rpm, the ESK clamping actuators are advantageous whenever the disadvantages of spring clamping are to be avoided and high clamping forces at relatively low rotational speed, as well as rigid spindle constructions are required. For their function they only require electrical energy which is available virtually everywhere.

Power Clamp Economic Plus EG Heat Shrink Systems

Single chuck system with cooling, without rotary table, tool tray optional.