320.002

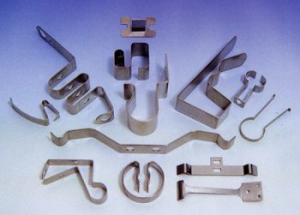

Gutekunst Leaf Springs

We use the following materials in any variant in manufacturing for our clients: 1.4310, 1.4301, CK 75 G, CK 75 H, CK 85, CK 101, CuSn6, CuZn37, CuBe2 Plus any other special material you may supply. We offer the following range of dimensions: strip thickness values of 0.1 to 3.0 mm, strip widths of 2.0 to 120 mm.

We use the following materials in any variant in manufacturing for our clients:

1.4310, 1.4301, CK 75 G, CK 75 H, CK 85, CK 101, CuSn6, CuZn37, CuBe2

Plus any other special material you may supply.

We offer the following range of dimensions: strip thickness values of 0.1 to 3.0 mm, strip widths of 2.0 to 120 mm.

As for the finishing we offer: vibratory grinding, hardening, bronzing, galvanizing, chroming, tin-coating, lacquering and coating.

For more information regarding this item (Gutekunst Leaf Springs) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Tension and Torsion Springs

We are able to offer our customers tension, torsion and individual form springs made of round, square or flat wire as well as of strip steel for all kinds of applications.

Square Springs

We are your specialists in the manufacturing of square springs for industrial use. Our standard springs are made of 1.4310 material with a wire thickness of 1.0 mm. Other materials and thickness values are available at request.

Compression Springs Overview

Steel springs from Gutekunst are manufactured using spring steel wire material no.1.4310 in compliance with EN 10270 part 3 (AISI 302 / BS 301S21). The tolerances of the wire diameters comply with DIN 2076.

Special Multi-Characteristic Springs

Röhrs special springs with two characteristics are a specialty, in which two spring characteristics are combined into one spring.

Multi-Wire Springs

Multi-wire springs are made of wire strands with various strand structures and are put to use as compression, torsion, tension and form springs.

Flat Wire Compression Springs

Compression springs made from flat wire

- wound to the spring axis

- offer the advantage of higher energy absorption at the same installation space compared to round wire compression springs. Furthermore, flat wire compression springs are more resistant to buckling and will encounter no friction martensite at high frequencies

-- unlike round wire compression springs, where the life expectancy is reduced. Our in-house rolling mills allow us to roll and process high-quality spring steels to the specific wire profiles our customers need. By choosing the right wire profile and spring dimensions, both linear and progressive characteristics can be realized.

Round Wire Compression Springs

Round wire compression springs are used in countless applications and fulfill / meet the widest range of technical requirements. We calculate the ideal spring design and select the appropriate spring material according to the load and environmental conditions. We can guarantee our customers the highest quality of our products.

Special Automotive Springs

Roehrs automotive exhaust system springs are designed for use between the engine and exhaust system. They utilize a fully elastic suspension to minimize bending stress, and are designed for absorption of axial forces and torsion at temperatures up to 400 °C. The springs minimize noise and help to extend the lifetime of the exhaust system since they are constructed of corrosion resistant materials.