440.110.C10.000

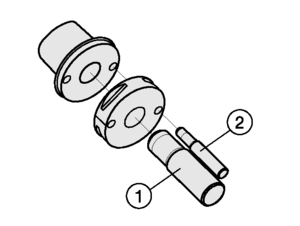

PSC (PSK) Tool Changer Alignment Gauges - Capto C10 Tool Changer Alignment Gauge

Polygonal-Shank Taper (PSK) Tool Changer Alignment

| Product | Gauge |

| Part Type | Tool Changer Alignment |

| Taper / Standard | PSK |

| Taper Size | C10 |

| Taper | Part Number | |||||||

|---|---|---|---|---|---|---|---|---|

| Capto C3 Tool Changer Alignment Gauge | 440.110.C03.000 | |||||||

| Capto C4 Tool Changer Alignment Gauge | 440.110.C04.000 | |||||||

| Capto C5 Tool Changer Alignment Gauge | 440.110.C05.000 | |||||||

| Capto C6 Tool Changer Alignment Gauge | 440.110.C06.000 | |||||||

| Capto C8 Tool Changer Alignment Gauge | 440.110.C08.000 | |||||||

| Capto C8X Tool Changer Alignment Gauge | 440.110.C08X.000 | |||||||

| Capto C10 Tool Changer Alignment Gauge | 440.110.C10.000 |

For more information regarding this item (PSC (PSK) Tool Changer Alignment Gauges - Capto C10 Tool Changer Alignment Gauge) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Capto Tool Changer Alignment Instruction Manual

The tool changer alignment tool is to verify proper alignment between the automatic tool changer (ATC) and the spindle or clamping unit. See PDF for full instruction manual.

PSC / PSK Spindle Runout Test Arbors

Made to the ISO 26623 Standard. Maximum runout error 0.003mm / 3 micron / 0.00012”. A certificate of accuracy is included. Storage are cases not included.

ForceCheck Force Gauge Base Set - Wired

Sets include display, connecting cable, and carrying case. Measuring bars, adapters, and other accessories are ordered separately.

ForceCheck Drawbar Force Gauge Base Set, Wireless

Sets include wireless display and carrying case. Measuring bars, adapters, and other accessories are ordered separately.

Machine-Integrated Drawbar Force Gauges

The machine-integrated drawbar force gauge automates drawbar force measurement. With a wireless force sensor stored in the tool changer, a machine can periodically automatically check the drawbar without stopping production. Drawbar force is returned to the machine control via a wireless receiver, automatically alerting the operator if insufficient force is detected.