461.200

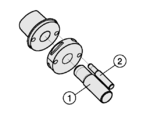

ForceCheck Drawbar Clamping Force Gauges, Wired

Tool clamping force is often never measured after a machine is put into service. Regular verification allows problems to be detected early so maintenance and repairs can be scheduled. As a result, emergencies and unexpected downtime can be avoided. When troubleshooting, drawbar performance can quickly be verified.

ForceCheck Force Gauge Base Set - Wired

Sets include display, connecting cable, and carrying case. Measuring bars, adapters, and other accessories are ordered separately.

| Part Number | ||||||||

|---|---|---|---|---|---|---|---|---|

| ForceCheck Base Set | 461.310.000.000 |

HSK Drawbar Force Gauge Sensors, Wired

Wired Forcecheck sensors also require a wired display unit and connecting cable to fully function.

Steep Taper (CAT/ANSI) Wired ForceCheck Sensors

Wired Forcecheck sensors also require a wired display unit and connecting cable to fully function.

Steep Taper (BT) Wired ForceCheck Sensors

Wired Forcecheck sensors also require a wired display unit and connecting cable to fully function.

| ForceCheck Sensor, Wired | Part Number | |||||||

|---|---|---|---|---|---|---|---|---|

| Steep Taper (BT) 30 | 461.200.730.000 | |||||||

| Steep Taper (BT) 35 | 461.200.735.000 | |||||||

| Steep Taper (BT) 40 | 461.200.740.000 | |||||||

| Steep Taper (BT) 50 | 461.200.750.000 | |||||||

| ForceCheck Base Set | 461.310.000.000 |

Steep Taper (DIN) Wired ForceCheck Sensors

Wired Forcecheck sensors also require a wired display unit and connecting cable to fully function.

PSK/PSC Wired ForceCheck Sensors

Wired Forcecheck sensors also require a wired display unit and connecting cable to fully function.

| ForceCheck Sensor, Wired | Part Number | |||||||

|---|---|---|---|---|---|---|---|---|

| PSK/PSC C3 | 461.200.C03.000 | |||||||

| PSK/PSC C4 | 461.200.C04.000 | |||||||

| PSK/PSC C5 | 461.200.C05.000 | |||||||

| PSK/PSC C6 | 461.200.C06.000 | |||||||

| PSK/PSC C8 | 461.200.C08.000 | |||||||

| PSK/PSC C10 | 461.200.C10.000 | |||||||

| PSK/PSC C8X | 461.200.C8X.000 |

KM Wired ForceCheck Sensors

Wired Forcecheck sensors also require a wired display unit and connecting cable to fully function.

| ForceCheck Sensor, Wired | Part Number | |||||||

|---|---|---|---|---|---|---|---|---|

| KM 32 | 461.200.K32.000 | |||||||

| KM 40 | 461.200.K40.000 | |||||||

| KM 50 | 461.200.K50.000 | |||||||

| KM 63 | 461.200.K63.000 | |||||||

| KM 6350 | 461.200.K65.000 | |||||||

| KM 80 | 461.200.K80.000 | |||||||

| KM 100 | 461.200.K90.000 | |||||||

| KM 10080 | 461.200.K98.000 | |||||||

| KM4X 63 | 461.200.K63.04B | |||||||

| KM4X 100 | 461.200.K90.04B |

Steep Taper (ISO) Wired ForceCheck Sensors

Wired Forcecheck sensors also require a wired display unit and connecting cable to fully function.

| ForceCheck Sensor, Wired | Part Number | |||||||

|---|---|---|---|---|---|---|---|---|

| Steep Taper (ISO) 10 | 461.200.A10.000 | |||||||

| Steep Taper (ISO) 15 | 461.200.A15.000 | |||||||

| Steep Taper (ISO) 20 | 461.200.A20.000 | |||||||

| Steep Taper (ISO) 25 | 461.200.A25.000 |

ForceCheck Sensor for Lyndex-Nikken NC5

Wired Forcecheck sensors also require a wired display unit and connecting cable to fully function.

| ForceCheck Sensor, Wired | Part Number | |||||||

|---|---|---|---|---|---|---|---|---|

| Lyndex-Nikken NC5-46 | 461.200.L46.000 | |||||||

| Lyndex-Nikken NC5-53 | 461.200.L53.000 | |||||||

| Lyndex-Nikken NC5-63 | 461.200.L63.000 | |||||||

| Lyndex-Nikken NC5-85 | 461.200.L85.000 | |||||||

| Lyndex-Nikken NC5-100 | 461.200.L90.000 |

This critical performance – the tool clamping force – is often never measured after a machine is put into service. Regular verification allows problems to be detected early so maintenance and repairs can be scheduled. As a result, emergencies and unexpected downtime can be avoided. When troubleshooting, drawbar performance can quickly be verified.

For more information regarding this item (ForceCheck Drawbar Clamping Force Gauges, Wired) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

HSK Tool Holder Taper Inspection Gauge

Designed to detect tool holder taper wear in seconds.

The tool holder taper inspection gauge includes two Fixture Bases, two 0.001mm Indicators, and a carrying case. An optional 410.148 certified Taper Master is strongly recommended for zeroing the Indicators. If a master is not available, a known good tool holder can be used in place of the master. Click the Details Tab for more information.

Spindle Runout Test Arbors

-Maximum runout error 0.003mm / 3 micron / 0.00012 inch

-Cylindricity ≤ 0.002mm / 2 micron / 0.00008 inch

-Carrying cases are not included. Visit www.tac.us/runoutcases for available case styles (Data Sheet 465.006).

-A certificate of accuracy is included. Traceable certificates available; contact us for details.

-Contact us for other lengths, tapers, and other special requirements.

Drawbar Clamping Force Gauges, Wired

Tool clamping force is often never measured after a machine is put into service. Regular verification allows problems to be detected early so maintenance and repairs can be scheduled. As a result, emergencies and unexpected downtime can be avoided. When troubleshooting, drawbar performance can quickly be verified.

Indicators and Bases

TAC Rockford offers a variety of magnetic bases and indicators for use with runout test arbors and other gauges.

Available as kits with storage case or individually.

HSK Tool Changer Alignment Gauges

Available for HSK-A 25, 32, 40, 50, 63, 80, 100, 125, and 160. Includes padded storage case.

Steep Taper Tool Changer Alignment Gauges

Available for Steep Taper 30, 40, 50, and 60. Includes padded storage case.

PSC (PSK) Tool Changer Alignment Gauges

Available for Polygonal-Shank Taper sizes C3, C4, C5, C6, C8, C8X, C10. Includes padded storage case.

KM Tool Changer Alignment Gauges

Improper alignment can result in abnormal wear on the spindle interface, tool changer, and tool holder.

In addition, mis-clamping and dropped tools can also occur.

KM gauges are available for ISO 26622 as well as Mazak Integrex flanges.

Sets include taper and flange, axial and radial alignment pins, and a padded carrying case.