685.AZS.050.B00

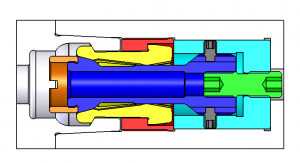

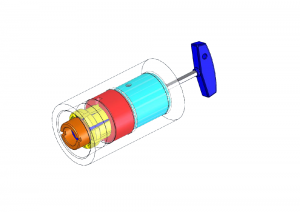

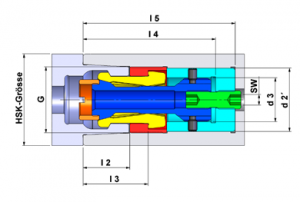

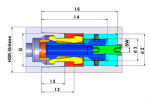

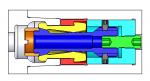

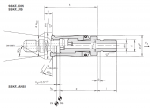

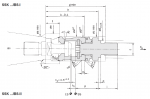

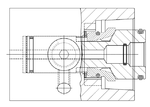

HSK-A/C/E50+B/D/F63 Axial-Clamp Manual Gripper, Version B (Direct Installation)

| HSK-A | HSK-B | Key Size | Torque | Force | Part Number | |||

|---|---|---|---|---|---|---|---|---|

| HSK-A/C/E 32 | HSK-B/D/F 40 | 4 | 3 Nm | 9 kN | 685.AZS.032.B00 | |||

| HSK-A/C/E 40 | HSK-B/D/F 50 | 4 | 6 Nm | 20 kN | 685.AZS.040.B00 | |||

| HSK-A/C/E 50 | HSK-B/D/F 63 | 5 | 10 Nm | 30 kN | 685.AZS.050.B00 | |||

| HSK-A/C/E 63 | HSK-B/D/F 80 | 6 | 12.5 Nm | 40 kN | 685.AZS.063.B00 | |||

| HSK-A/C/E 80 | HSK-B/D/F 100 | 8 | 18 Nm | 60 kN | 685.AZS.080.B00 | |||

| HSK-A/C/E 100 | HSK-B/D/F 125 | 8 | 25 Nm | 80 kN | 685.AZS.100.B00 |

For more information regarding this item (HSK-A/C/E50+B/D/F63 Axial-Clamp Manual Gripper, Version B (Direct Installation)) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Mounting Nuts for HSK-A/C Interface Adaption

Can be mounted in front of the spindle shaft after the installation of the collet. Has the advantage of being adaptable to HSK-E or HSK-F tool interfaces in an HSK-A spindle. Just use the drive key to expand and then clamp the desired tool. The ENS slot nuts can also be used in manual clamping units for more flexibility. Available for HSK 32, 40, 50, 63, 80, and 100.

Transfer Rail Couplings

The mechanical self-locking Berg gripper rail coupling GSM is designed for manual coupling of gripper rails on transfer presses. A vertical lift-out stroke is required for changing the tool.

HSK-C 4 Point Manual Clamping Sets for Conventional Cooling

- For a coolant pressure up to 80 bar - Includes installation and operating instructions

HSK-F Tool Holder Blanks

TAC Rockford stocks HSK-F63 blanks. Other sizes are available on request.

Steep Taper Grippers SSKF

With an easy-to-machine spindle contour, BERG Spanntechnik SSKF gripper is designed for cost-sensitive applications.

Steep Taper Grippers SSK-JBS

SSK gripper are primarily designed for drawing in and ejecting steep taper tooling provided with retention knobs internationally standardized as per DIN, ANSI, MAS, JIS and ISO which allow fast automatic tool changes. SSK grippers are not only suitable for clamping tools, but also workpieces or workpiece holders and pallets on machining centers, milling machines, boring machines, grinding centers, special purpose machines, and handling systems.

Rear-Clamp Manual Clamping Cartridges

355.621 series manual clamping cartridges are suitable for HSK-E and HSK-F holders that do not have drive key slots or an access hole on the side of the taper. In addition, the center bolt is compatible with standard HSK coolant tubes.

Steep Taper Tool Changer Alignment Gauge Instruction Manual

The tool changer alignment gauge is designed to verify correct alignment of the machine spindle to the tool changer. See PDF for full instruction manual.