250.506

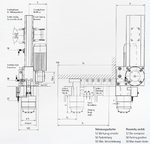

Application: Small Capacity Chain-Type Automatic Tool Changers

For more information regarding this item (Application: Small Capacity Chain-Type Automatic Tool Changers) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Automatic Hydraulic Push Drive Chain-type Clamping Systems

The push drive chain-type hydraulic die clamping system is designed for clamping dies of various widths on press slides. The push-pull chain actuator moves automatically in the T-slot of the press slide between the parking position and the respective die. Hydraulic pressure is at a maximum 400 bar. The push-pull chain actuator can be used alternative to the PSV/PLV clamping actuator for every BERG press clamping system.

Application: Drum/Disc-Type Automatic Tool Changers

Drum (or disc) style tool changers are a common option for fast availability of a smaller number of tools. They are designed for easy integration into machining centers.

Tool Dynamic TD 1002 Tool Balancing Systems

Balancing Machine to balance tool holders on 1 and 2 planes.

- At reasonable price (no PC)

- Table and complementary machine

- Ideal for mould makers

- For small batch lots, single application and standard chucks

- Adapter with automatic clamping system

TULMOBIL Tool Carriers Model OS1

To accommodate 8 tool carriers at an angle on aluminum profile rails. In the top and bottom steel frame a further 8 carriers or small storage boards or trays can be inserted. With 2 swivel castors (one with locking device), 2 fixed castors, push handle and 4 aluminum profile rails.

Tall Cabinets with Removable Shelves

Used for general storage of machine shop equipment and other small parts. With 4 removable shelves (load capacity 100 Kg/shelf). A transportation base with a height of 100 mm is already integrated.

Machine-Integrated Drawbar Force Gauges

The machine-integrated drawbar force gauge automates drawbar force measurement. With a wireless force sensor stored in the tool changer, a machine can periodically automatically check the drawbar without stopping production. Drawbar force is returned to the machine control via a wireless receiver, automatically alerting the operator if insufficient force is detected.

Hollow Taper Shank Type A

For use with machining centers, milling machines, special-purpose machines with automatic tool changing. Hollow Taper Shanks for Automatic Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 with Gripper Groove.

KM Spindle Runout Test Arbors

- Maximum runout error 0.003mm [0.00012 in.]

- Carrying cases are not included. Visit www.tac.us/runoutcases for available case styles (Data Sheet 465.006).

- A certificate of accuracy is included. Traceable certificates available; contact us for details.

- Contact us for other lengths, tapers, and other special requirements.

* ISO 26622 runout arbor tapers are compatible with machines using TS, XMZ (Mazak Integrex), and ATC. Flange may not be suitable for use with automatic tool changers.