250.502

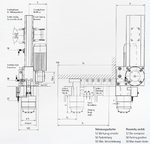

Application: Large Capacity Chain-Type Automatic Tool Changers

For more information regarding this item (Application: Large Capacity Chain-Type Automatic Tool Changers) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Automatic Hydraulic Push Drive Chain-type Clamping Systems

The push drive chain-type hydraulic die clamping system is designed for clamping dies of various widths on press slides. The push-pull chain actuator moves automatically in the T-slot of the press slide between the parking position and the respective die. Hydraulic pressure is at a maximum 400 bar. The push-pull chain actuator can be used alternative to the PSV/PLV clamping actuator for every BERG press clamping system.

Application: Drum/Disc-Type Automatic Tool Changers

Drum (or disc) style tool changers are a common option for fast availability of a smaller number of tools. They are designed for easy integration into machining centers.

Machine-Integrated Drawbar Force Gauges

The machine-integrated drawbar force gauge automates drawbar force measurement. With a wireless force sensor stored in the tool changer, a machine can periodically automatically check the drawbar without stopping production. Drawbar force is returned to the machine control via a wireless receiver, automatically alerting the operator if insufficient force is detected.

Hollow Taper Shank Type A

For use with machining centers, milling machines, special-purpose machines with automatic tool changing. Hollow Taper Shanks for Automatic Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 with Gripper Groove.

Hollow Taper Shank Type D

For use in all areas which require even better support with manual tool changing via a large contact face. Hollow Taper Shanks for Manual Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 without Gripper Groove.

KM Spindle Runout Test Arbors

- Maximum runout error 0.003mm [0.00012 in.]

- Carrying cases are not included. Visit www.tac.us/runoutcases for available case styles (Data Sheet 465.006).

- A certificate of accuracy is included. Traceable certificates available; contact us for details.

- Contact us for other lengths, tapers, and other special requirements.

* ISO 26622 runout arbor tapers are compatible with machines using TS, XMZ (Mazak Integrex), and ATC. Flange may not be suitable for use with automatic tool changers.

TRIBOS Application Example with SRE-R and SVP

An example TRIBOS application with SRE-R inserts and SVP clamping devices.

Tool Dynamic TD 1002 Tool Balancing Systems

Balancing Machine to balance tool holders on 1 and 2 planes.

- At reasonable price (no PC)

- Table and complementary machine

- Ideal for mould makers

- For small batch lots, single application and standard chucks

- Adapter with automatic clamping system