293-BKZ-PKV

BERG Automatic Hydraulic Push Drive Chain-type Clamping Systems

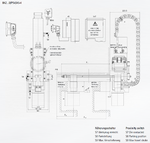

Self-traveling (Automatic) quick die changing system with push drive chain style clamping

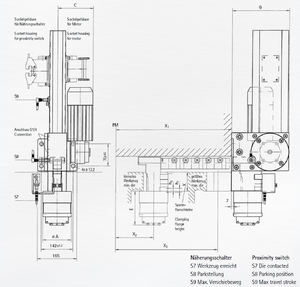

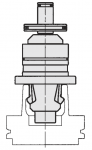

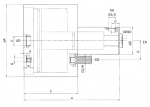

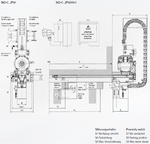

The push drive chain-type hydraulic die clamping system is designed for clamping dies of various widths on press slides. The push-pull chain actuator moves automatically in the T-slot of the press slide between the parking position and the respective die. Hydraulic pressure is at a maximum 400 bar. The push-pull chain actuator can be used alternative to the PSV/PLV clamping actuator for every BERG press clamping system.

![]() PDF Data Sheet: BERG Automatic Hydraulic Push Drive Chain-type Clamping Systems (293-BKZ-PKV)

PDF Data Sheet: BERG Automatic Hydraulic Push Drive Chain-type Clamping Systems (293-BKZ-PKV)

For more information regarding this item (BERG Automatic Hydraulic Push Drive Chain-type Clamping Systems) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Capto Hydraulic Self-Locking Clamping Systems

The self-limiting clamping system for Coromant Capto tools developed by BERG Spanntechnik is used in conjunction with Coromant Capto clamping sets. In this solution the wedge drive is rigidly connected to the clamping set via a drawbar.

HSK Hydraulic Self-Locking Clamping Systems

The self-limiting clamping system for HSK tools developed by BERG Spanntechnik is used in conjunction with the proven HSH clamping sets. In this solution the wedge drive itself is rigidly connected to the clamping set via a drawbar.

Self-Traveling Clamping Systems

Electromechanical PSP...VL/PLV Clamp for die clamping on slides. The clamp automatically travels between the park position and the actual die, guided by the T-slot of the slide. The bell-crank lever covers a wide clamping range.

Steep Taper Hydraulic Self-Locking Clamping Systems

The self-limiting clamping system for quick-release taper tools developed by BERG Spanntechnik is used in conjunction with the proven SSK clamping sets. In this solution the wedge drive itself is rigidly connected to the clamping set via a drawbar.

HDT Tool Clamping Cylinders

HDT pressure intensifiers are primarily designed for tool clamping and chucking systems using stationary hydraulic cylinders of the type HLZ for releasing the tool shanks when no hydraulic unit is available for operating them.

Automatic Hydraulic C-clamping Systems

The C-clamping hydraulic die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the park position and the respective die. Hydraulic pressure is at a maximum 400 bar

Hydraulic Power Stations for Hydraulic Quick Die Clamping Systems

Hydraulic power stations for quick die clamping systems are designed for actuating hydraulic clamping elements in the forming presses. A large number of electro-hydraulic (HA) or air-hydraulic power stations (HAL) are available depending on the use of the clamping elements and/or hydraulics on the press plunger or on the table, as well as the number of clamping elements.

Automatic Hydraulic Drawbar Style Clamping Systems

The hydraulic die clamping system with drawbar style clamping is designed for clamping dies of different widths on press slides. The clamping actuator moves automatically into the T-slot of the press slide between the parking position and the respective die. The clamping element can clamp different clamping rim heights due to the long clamping stroke of the double acting cylinder. Hydraulic pressure is at a maximum 400 bar.