942.44412

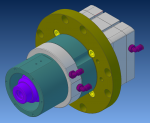

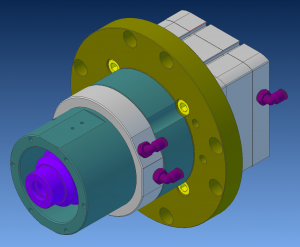

Application: Robotic Pneumatic End Effector for Manipulating HSK-A100 Tool Holders

Customer required an automated mechanism to be mounted on the end of a robot. To ensure reliable operation, numerous sensing and other features were implemented: - Pneumatic cylinder stroke monitoring (ensures correct tool clamp) - Fiber optic tool sensor (ensures proper tool seating) - Backflow air sensor (ensures proper tool face contact when seated) - Air purge on HSK face and taper (ensures surfaces are free of debris) This unit was designed for HSK-A100, but the concept can be applied to all machine tool tapers designed for automatic tool change (other HSK sizes, Steep Taper, PSK/Capto, etc.)

For more information regarding this item (Application: Robotic Pneumatic End Effector for Manipulating HSK-A100 Tool Holders) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

HSK-A Tool Holder Blanks

TAC Rockford stocks HSK-A32, HSK-A40, HSK-A50, HSK-A63, HSK-A80, HSK-A100, and HSK-A125 in a variety of diameters and lengths. HSK-A160 blanks are available on request as well.

HSK to Steep Taper Adapters

Application: for holding steep taper tool holders in an HSK spindle.

HSK-A Shell End Mill Arbors for Cutters with Internal Cooling

For Shell end mills with driving slot DIN 138. Available for HSK-A 50, 63, 80, 100.

HSK-A Whistle-Notch Holders

For end mills with shank DIN 1835-B and / or DIN 1835-E. The hole diameter and circular deviation tolerances have been significantly tightened up compared with DIN 1835 in order to achieve the highest levels of machining precision. Balanced according to ISO 1940-1 up to 10,000 rpm. Available for HSK-A 32, 40, 50, 63, 80, 100.

HSK-A Weldon Holders

For end mills with shank DIN 1835-B

- DIN 6535 HB. The hole diameter and circular deviation tolerances have been significantly tightened up compared with DIN 1835 in order to achieve the highest levels of machining precision. Balanced according to ISO 1940-1 up to 10,000 rpm. Available for HSK-A 32, 40, 50, 63, 80, 100.

HSK-C Weldon and Whistle-Notch Holders

The hole diameter and circular deviation tolerances have been significantly tightened up compared with DIN 1835 in order to achieve the highest levels of machining precision. Available for HSK-C 32, 40, 50, 63.

HSK-E Weldon Holders

The hole diameter and circular deviation tolerances have been significantly tightened up compared with DIN 1835 in order to achieve the highest levels of machining precision. Available to HSK-E 25, 32, 40, 50, 63.

Pneumatic HSK Spindle Gauge Kits

Gauging kit for HSK spindles with pneumatic measuring system. The Multifunctional Measuring and Control Device is designed for high precision and multifunctional capabilities. In addition to providing various ways for measuring input, it can be customized to meet customer requirements.