687.MN5219-07

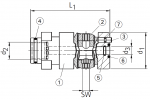

HSK-C50 KS Clamping Installation Tool

| Product | Accessory |

| Part Type | Adapter Flange |

For more information regarding this item (HSK-C50 KS Clamping Installation Tool) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

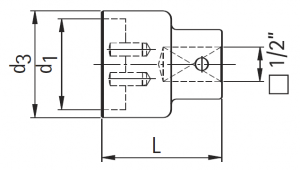

KS Installation Tools

Available for HSK-C 32, 40, 50, 63, 80, 100

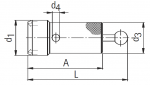

Clamping Cartridge Installation Tools

For the installation of 4-point clamping sets, if there are difficulties locking the spindle.

Mounting Nuts for HSK-A/C Interface Adaption

Can be mounted in front of the spindle shaft after the installation of the collet. Has the advantage of being adaptable to HSK-E or HSK-F tool interfaces in an HSK-A spindle. Just use the drive key to expand and then clamp the desired tool. The ENS slot nuts can also be used in manual clamping units for more flexibility. Available for HSK 32, 40, 50, 63, 80, and 100.

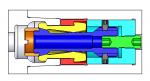

HSK-C 4 Point Manual Clamping Sets for Conventional Cooling

- For a coolant pressure up to 80 bar

- Includes installation and operating instructions

HSK-C PowerClamp Manual Clamping Sets

- For coolant up to 80 bar

- Includes installation and operating instructions

- Includes threaded pin

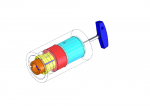

KS Clamping Cartridges for Minimal Lubrication (MLC)

Available for HSK-C 40, 50, 63, 80, 100

Manual Drawbar Style Hydraulic Clamping Systems

The drawbar style hydraulic die clamping systems are designed for clamping tools and dies of different widths on press slides. The BKZ-PS variant is equipped with a non-return valve. The BKZ-D (D = Double-acting) variant is intended for use in confined installation spaces where short clamping and/or release times are required. The BKZ-K (K = Cup) variant compensates for nonparallel tool clamping surfaces. The die clamps can be manually moved in the T-slot of the press slide between the parking position and the respective tool. Hydraulic pressure is at a maximum 400 bar.

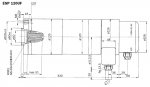

ESP UF Tool Clamping Cylinders

ESP UF electro-mechanical actuators are intended for the power actuated clamping and release of steep taper tooling on milling and boring machines on which the tool change is performed manually. They are firmly connected by way of appropriate connection pieces to the workspindle which has a maximum rotational speed of 4000 rpm. The electrical control can be per formed both manually and automatically.