240.350

Hydrostatic Rotary Tables

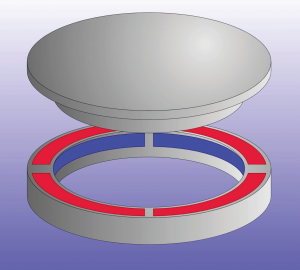

Application example of a glass grinding machine used at Zeiss.

Blue: Radial Bearing

Red: Axial Bearing

Application ExampleDiameter: 1315 mm

Maximum Speed: 5 RPM

Load: 75 • 250 kN

Maximum Torque Load: 100 kNM

Stiffness: 46.5 kN/micro-m

Power Requirement: 0.28 kW max.

Used for Glass Grinding Machine at Zeiss

For more information regarding this item (Hydrostatic Rotary Tables) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

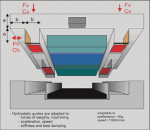

Application: Hydrostatic Rotary Tables

The world's largest gear and profile grinding machines use hydrostatic bearings.

Hydrostatic Leadscrews

- Speed comparable to a linear motor

- Very low friction when machining, virtually frictionless

during positioning

- Steps in the 0.1 micron range are possible

- No backlash when reversing direction

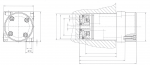

CBN Hydrostatic Grinding Spindle Systems

This is an example of a hydrostatic spindle designed for high speed grinding with CBN grinding wheels. The small bearing diameter in combination with high surface speed allows the use of CBN wheels even for undercuts in a camshaft application.

Hense Pneumatic Rotary Actuators

Hense rotary actuators provide an effective and economic solution for angular or straight motion when high force and torque is required.

Hydrostatic Application Worksheet

Download the PDF data sheet for the Hydrostatic Application Worksheet

Hydrostatic Linear Motor Guide

The PM Flow Controller makes it possible for machine builders to easily integrate custom hydrostatic systems into both new and existing machines.

Rotary Transmission Leadthroughs HDF

Rotary transmission leadthroughs serve as a rear inter face for fluid transmission into the spindle. A hydromechanic clamping unit or integrated clamping cylinder can be actuated with the media oil, air and coolant. The transmission of oil and coolant is possible at rotational speed.

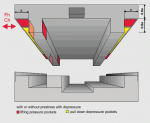

Hydrostatic Slides

- Very low friction, no friction at positioning

- Movement of 0.1 micro-m possible

- No reversal backlash of friction force

Power Clamp Economic Plus EG Heat Shrink Systems

Single chuck system with cooling, without rotary table, tool tray optional.