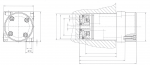

291-CAPTO

BERG Capto Clamping Systems

BERG Spanntechnik is a leading supplier of Capto grippers and clamping systems.

Application

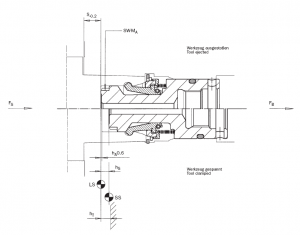

These gripper sets allow a substantial reduction in chip-to-chip times in conjunction with fast tool changers. BERG Spanntechnik, as a system partner of SANDVIC Coromant, supplies customized tool clamping devices for the Capto interface with detenting clamping sets.

Design Features

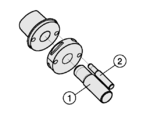

Coromant Capto clamping sets have 6 collets which are held by an annular spring and perform a tilting movement for changing and removing the tool. The Capto R clamping system offers an additional detent function which retains the tool securely in the spindle in the release position.

For more information regarding this item (BERG Capto Clamping Systems) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Capto Hydraulic Self-Locking Clamping Systems

The self-limiting clamping system for Coromant Capto tools developed by BERG Spanntechnik is used in conjunction with Coromant Capto clamping sets. In this solution the wedge drive is rigidly connected to the clamping set via a drawbar.

PSC (PSK) Tool Changer Alignment Gauges

Available for Polygonal-Shank Taper sizes C3, C4, C5, C6, C8, C8X, C10. Includes padded storage case.

Overview: Clamping Systems with AS-Interface

The BERG AS-Interface clamping and chucking systems are intended for clamping various tools/dies on press slides and black holders, and for sliding table clamping and gripper rail couplings on multiple die presses. They are used on new machines and for retrofitting automatic clamping systems in existing press lines.

Hydraulic Power Stations for Hydraulic Quick Die Clamping Systems

Hydraulic power stations for quick die clamping systems are designed for actuating hydraulic clamping elements in the forming presses. A large number of electro-hydraulic (HA) or air-hydraulic power stations (HAL) are available depending on the use of the clamping elements and/or hydraulics on the press plunger or on the table, as well as the number of clamping elements.

Drawbar Force Gauges

The BERG clamping force measuring system for the tool holders is designed for force measurement when the spindle is stationary! The measuring system consists of a handy sturdy display device in pocket calculator format and the measuring equipment required for the various application. The measured data can be transferred to any WIN 9x/NT PC via a serial standard inter face and represented in y/t. The measuring system includes a practical case for accommodating the display device, the measuring equipment, the charger and the connecting cable.

PSK/PSC Adaptor Flanges

Capto (Polygonal Taper) adapter flanges are a one-piece design available for C3, C4, C5, C6, C8 PSC tapers. Ideal for tool holder blank building or other mounting capabilities with the Coromant Capto tool holder system.

Workpiece Holding Clamping Systems

BERG-Spanntechnik offers an extensive range of power operated chucks and hydraulic cylinders which meet all the requirements of modern CNC lathes as there are effective clamping force, attainable numbers of rotation, and precision, as well as center hole width for bar stock.

Pallet Holding Force Gauges

Clamping force measuring gauges for pallets are intended to quickly measure the holding force of individual clamping heads.

Pallet clamping adapters are per-application based, and are fitted according to the specifications of the customer's pallet system.

Clamping adapters can be or have been provided for various pallet systems: BERG, Rohm, Mazak, OTT, Schunk, Erowa, and others.

Rotary Transmission Leadthroughs HDF

Rotary transmission leadthroughs serve as a rear inter face for fluid transmission into the spindle. A hydromechanic clamping unit or integrated clamping cylinder can be actuated with the media oil, air and coolant. The transmission of oil and coolant is possible at rotational speed.