490.510.080.250

Run-out and Setting Arbors for Turning Machines

| Part Number | ||||||||

|---|---|---|---|---|---|---|---|---|

| Runout Arbor for Chucks, D=60 L=150 | 490.510.060.150 | |||||||

| 490.510.070.200 | ||||||||

| 490.510.080.250 | ||||||||

| 490.510.090.315 | ||||||||

| 490.510.100.400 | ||||||||

| 490.510.125.500 | ||||||||

| 490.510.140.630 |

For more information regarding this item (Run-out and Setting Arbors for Turning Machines) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

A2 and D1 Flanged Lathe Spindle Runout Test Bars

Test arbor for mounting to turning-center and measuring run-out. Designed for A2-5, A2-6, D1-8 etc. lathe face mounting. Also available for flat 110 and 140 lathe face.

Runout Arbors for Centers

TAC Rockford runout arbors for lathe centers are manufactured using hardened gauge-quality steel, and include a certificate of accuracy.

HSK PowerClamp Adapter Flanges for Turning Machines

- For fixed tools

- Includes setting element to eliminate drive play with vertical tools

- Includes clamping set

- Includes brass locking ring

- Includes indexing pin and retention screws

KM Precision Ball-End Runout Test Arbors

Ball end spindle runout test arbors are designed checking positioning accuracy of 5-axis machines, but can also be used in place of a standard runout test bars when a shorter length is required or for a touchoff point from the spindle face (ball end is ideal for this purpose).

Our 467 precision version feature an adjustment mechanism which allows for improved accuracy.

* ISO 26622 runout arbor tapers are compatible with machines using TS, XMZ (Mazak Integrex), and ATC. Flange may not be suitable for use with automatic tool changers.

Morse Taper Spindle Runout Arbors

Morse taper runout arbors offer a quick and easy way to verify correct spindle runout for machines with Morse tapers. Included is a threaded spanner nut to facilitate removable from the Morse spindle.

Arbors are manufactured to standard DIN 229 with a metric thread. Contact us for different sizes or customized versions.

Custom-Built Machine Gauges

We can build custom gauges for any machine or machine designed specifically for any application and requirements

-- even gauges not designed or built by anyone else! Interface options include multi-language support, multiple measuring capabilities, and any communication method.

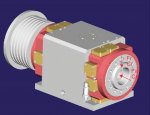

Rotary Unions for High Speed Applications and Dry Run

The unions for the models A and B have been designed for machine tool spindles rotating at high speed with fluid passing through or dry when needed. The seals, balanced and microlapped, remain always closed without problems both with fluid passing through (wet run) or without fluid (dry run).

Steep Taper Precision Ball-End Runout Test Arbors

Our 467 precision version feature an adjustment mechanism which allows for improved accuracy when compared to our standard 466 ball arbors.

Hydrostatic Lathe Spindles

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the

workpiece. Heat that is generated is moved immediately out of the spindle area with the oil and cooled in the chiller.

- No vibration from roller bearings for extremely smooth operation.

- Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.