468.200

Vibration Meter

Measures velocity and acceleration. The large display indicates RMS, peak, min/max, hold, and low battery. Features an auto power off. Comes ready to use in a foam-lined, hardshell carrying case, with a detachable magnetic probe, 9V battery and instructions.

| Part Number | ||||||||

|---|---|---|---|---|---|---|---|---|

| Portable Vibration Meter | 468.200.840063 |

For more information regarding this item (Vibration Meter) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Engine and Machinery Mounts

Steel-spring combination for high efficient shock and vibration absorption in order to avoid creep from elastomer springs and readjustment of machines respectively. We provide custom-designed mounts for all kinds of machines and engines (fixation on the side, straight fixation, universal fixation, fixation of the edge).

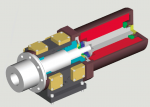

Hydrostatic Grinding Spindles with Integral Motors

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the

workpiece.

- Heat that is generated is moved immediately out of the spindle area with the oil and

cooled in the chiller.

- No vibration from roller bearings for extremely smooth operation.

- Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.

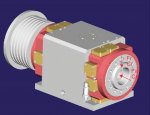

QDI Asynchronous Motors for Test Stands

High maximum speed, wide range of field weakening, very low vibration levels, and standard configuration with hybrid bearings. Contact us to adapt the electrical and mechanical design to your specific requirements.

Hydrostatic Lathe Spindles

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the

workpiece. Heat that is generated is moved immediately out of the spindle area with the oil and cooled in the chiller.

- No vibration from roller bearings for extremely smooth operation.

- Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.

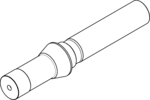

TF and BS Swiss-Style Collet Runout Test Arbors

TAC Rockford workholding spindle runout test bars provide a definitive standard for verifying the accuracy of 5C, TF, BS, and other collet spindles.

Designed for precision collet chucks, Swiss-style lathes, indexing heads, and grinding fixtures, a runout test bar provides an immediate, reliable baseline to diagnose spindle health, troubleshoot vibration issues, and certify machine alignment.

<b>Additional product information can be found on the Details tab below.</b>

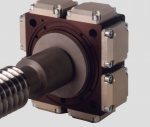

ForceCheck Hydraulic Tool Holder Force Gauges

Hydraulic tool holders are an excellent ultra-low option with added benefits such as vibration damping and ease of use. One of the major challenges with hydraulic holders is determining if they are still functioning correctly over time. Failure of the hydaulic holding mechanism is often not apparent until cutter slippage occurs, potentially causing damage to both the holder and a scrapped workpiece.

ForceCheck hydraulic tool holder force gauges provide a quick and reliable way to verify a tool holder is still operating correctly. The sensor measures the force at the center of the hydraulic sleeve.

Using the gauge is as easy as inserting the sensor in the hydraulic holder. Once the actuation piston compresses the hydraulic fluid in the expansion sleeve, the resulting force is shown on a handheld digital display. The measured force can be compared to a new or known-good hydraulic tool holder.

Hydrostatic Universal Bearings

- Frictionless even at minute revolutions

- Transmits minute rotating motion

- No backlash when reversing direction

- Slip-stick effect is eliminated

Hydrostatic Slides

- Very low friction, no friction at positioning

- Movement of 0.1 micro-m possible

- No reversal backlash of friction force

Spindle Runout Test Arbor Instructions

One of the leading causes of tool breakage, part finish issues, tolerance control, and machine registration issues is excessive spindle runout.