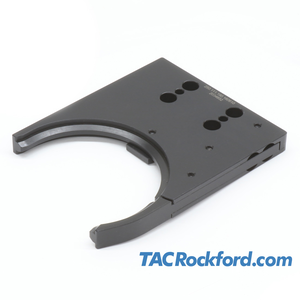

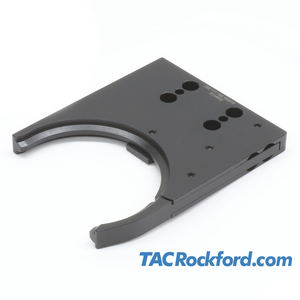

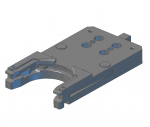

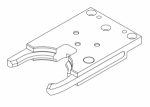

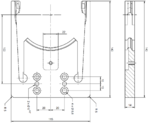

250.111.190.000

HSK-A100 Heavy Duty Tool Change Gripper, Single Articulated Finger

Contact us for optional orientation keys.

| Product | Component |

| Part Type | Tool Changer Gripper |

| Taper / Standard | HSK-A |

| Taper Size | 100 |

For more information regarding this item (HSK-A100 Heavy Duty Tool Change Gripper, Single Articulated Finger) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Heavy-Duty Tool Changer Grippers

Heavy duty grippers are designed for demanding applications and where total cost of machine ownership is considered (individual components are replaceable). These grippers have a pivoting finger that allows tool holding force to be adjusted by changing the internal spring. In addition, this unique design minimizes wear on the tool holder.

Contact us for optional orientation keys.

Heavy-Duty Locking Grippers

The locking gripper offers the same features as the heavy duty gripper, but adds the benefit of a locking mechanism to retain the tool. Because the tool cannot be removed from the gripper, this design is ideal for rapid acceleration or extremely heavy tools. Unlocking can be mechanical, electric, or pneumatic depending on customer requirements.

Hollow Taper Shank Type B

For use with machining centers, milling machines for heavy-duty machining, lathes. Hollow Taper Shanks for Automatic Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 with Gripper Groove.

Custom Heavy-Duty Gauge Case

Custom-cut foam heavy-duty gauge cases, made special to order for TAC Rockford gauge sets. Ideal for heavy gauges, test bars, test rings, and machine measuring cylinders.

EHHF and HHHF Handling Systems

The modular handling systems EHHF and HHHF are used as heavy duty grippers in various areas of machine tool and plant engineering.

Application: Robotic Pneumatic End Effector for Manipulating HSK-A100 Tool Holders

Customer required an automated mechanism to be mounted on the end of a robot. To ensure reliable operation, numerous sensing and other features were implemented:

- Pneumatic cylinder stroke monitoring (ensures correct tool clamp)

- Fiber optic tool sensor (ensures proper tool seating)

- Backflow air sensor (ensures proper tool face contact when seated)

- Air purge on HSK face and taper (ensures surfaces are free of debris)

This unit was designed for HSK-A100, but the concept can be applied to all machine tool tapers designed for automatic tool change (other HSK sizes, Steep Taper, PSK/Capto, etc.)

Axial Collet Clamping Grippers for HSK 100 Grinding Wheels

The AZS gripper is specially designed to manually mount heavy grinding wheels to a standard HSK 100 tool interface. The grinding wheel is mounted onto a HSK-style tool holder and is held to the spindle extremely accurately. The gripper allows very high clamping forces in a compact design. For example, the clamping force is 55 kN with a clamping torque of only 30 Nm for HSK 100. If needed, this AXS-100 gripper could be adapted for any HSK standard.

Overview: Heavy-Duty Tool Changer Grippers

TAC offers tool changer grippers for all tool holder types, with common sizes available from stock. We offer customization for specific needs (tool ID chip compatibility, special orientations, and other machine design requirements).

Custom Case Services

TAC Rockford can custom manufacture a gauge case to your exact requirements. Let us know what gauges you want to include in the case, and how you plan to use the case. Customized cases are available in heavy duty plastic, standard duty plastic, and Baltic Birch plywood. Foam is milled for for exact fit and optimal protection of gauges.