000.422

Clamping Force History Magnet Refills

Download and print this PDF for clamping force history forms. These can be placed on a CNC machine to track a preventive maintenance schedule and measure changes in clamping force over time. Contact us to order free magnetic packets to place the refill forms in.

![]() PDF Data Sheet: Clamping Force History Magnet Refills (000.422)

PDF Data Sheet: Clamping Force History Magnet Refills (000.422)

For more information regarding this item (Clamping Force History Magnet Refills) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

HSK Handbook

The HSK Handbook is recommended for end users involved in the implementation of HSK tooling, machine tool companies and distributors of CNC centers with HSK spindles, tooling departments responsible for HSK specifications, developers of HSK equipment and professionals looking for new tooling solutions for high speed/high rigidity machining.

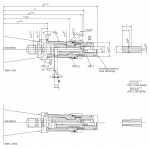

Senso 3000 Hydraulic Tool Holder Force Gauge

The SENSO 3000 is a specialized tool for verifying correct operation of hydraulic tool holders. For workholding collet force gauges, please see our ForceCheck collet force gauges.

SENSO 3000 determines the clamping force of the hydraulic chuck via a pressure sensitive plug gauge. The entire length of the plug gauge is clamped in the hydraulic chuck so that when tightening the clamping screw the clamping pressure of the chuck is optimally applied. The clamping force measuring instrument displays the clamping force as an absolute measurement value on the one hand and as a percentage clamping force in relation to a reference value that can be set individually on the other. This way, SENSO 3000 can be adapted to customer specific application conditions and requirements.

The clamping force measuring instrument is supplied with a plug gauge for the respective clamping diameter as well as a carbide proofing bar for calibration purposes and a CR 2430 type battery – all in a sturdy and handy case.

Pallet Holding Force Gauges

Clamping force measuring gauges for pallets are intended to quickly measure the holding force of individual clamping heads.

Pallet clamping adapters are per-application based, and are fitted according to the specifications of the customer's pallet system.

Clamping adapters can be or have been provided for various pallet systems: BERG, Rohm, Mazak, OTT, Schunk, Erowa, and others.

Workholding Collet Drawbar Force Gauge

ForceCheck collet force gauges measure the drawbar pullback force of a 5C, 16C, or 20C collet workholding system. Measurement of collet drawbar force provides an easy way to ensure correct force from machine to machine, or between setups for different parts.

Steep Taper Grippers SSKV

The BERG Spanntechnik SSKV incorporates a number of new technical innovations, including tool holding force intensification and a special tribolic coating to ensure the highest possible constant clamping force.

BERG Pallet Holding Force Gauges

Includes measuring case, display unit, measuring cartridge, test certificate, and clamping head specific pull studs

Hydrodock System

Hydrodock units form the basis of a very compact and flexible clamping system. They were originally conceptualized as for head change systems on large machining centers, but also find applications in diverse areas such as injection molding machines.

Machine-Integrated Drawbar Force Gauges

The machine-integrated drawbar force gauge automates drawbar force measurement. With a wireless force sensor stored in the tool changer, a machine can periodically automatically check the drawbar without stopping production. Drawbar force is returned to the machine control via a wireless receiver, automatically alerting the operator if insufficient force is detected.