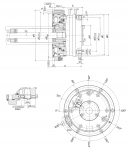

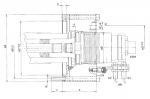

350.510

Air/Oil Clamping Cylinders

For more information regarding this item (Air/Oil Clamping Cylinders) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

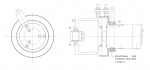

Rotary Transmission Leadthroughs HDF

Rotary transmission leadthroughs serve as a rear inter face for fluid transmission into the spindle. A hydromechanic clamping unit or integrated clamping cylinder can be actuated with the media oil, air and coolant. The transmission of oil and coolant is possible at rotational speed.

Hydraulic Power Stations for Hydraulic Quick Die Clamping Systems

Hydraulic power stations for quick die clamping systems are designed for actuating hydraulic clamping elements in the forming presses. A large number of electro-hydraulic (HA) or air-hydraulic power stations (HAL) are available depending on the use of the clamping elements and/or hydraulics on the press plunger or on the table, as well as the number of clamping elements.

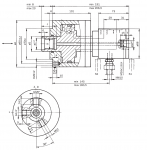

OHL and OHLK Tool Clamping Cylinders

Rotating hydraulic cylinders of the type OHLK..-1 and OHL..-1 are principally designed for actuating SK and HSK clamping sets. All coolant lubrication and compressed air supply variants are possible with a single device to meet the respective requirements. The control system is represented in the circuit diagram T 1345. Unlike spring actuated clamping and chucking systems, OHL(K) ..-1 hydraulic cylinders allow alteration of the clamping forces within wide limits. As the rotating cylinder is permanently connected to the spindle, no axial forces act upon the spindle bearings during tool release and ejection.

OSKL Tool Clamping Cylinders

OSKL rotating hydraulic cylinders are primarily designed for actuating SSK gripper, but are also suitable for operating other clamping and chucking systems.

Hydrostatic Center Bearings

- Only one radial bearing

- Moment and axial forces are carried by an axial bearing

- Integrated clamping piston and rotating oil union for a hydraulic collet. The clamping piston is driven with hydrostatic oil and released with springs.

- Extremely minimal friction (results in minimal warming during continuous operation, and more of the motor drive force applied to the workpiece).

HDT Tool Clamping Cylinders

HDT pressure intensifiers are primarily designed for tool clamping and chucking systems using stationary hydraulic cylinders of the type HLZ for releasing the tool shanks when no hydraulic unit is available for operating them.

Precision Granite Master Cylinders

TAC Rockford Precision Granite Master Cylinders are the standard for verifying the perpendicularity, straightness, and runout of critical machine axes on high-precision machine tools and CMMs. Manufactured from select, high-density black granite, these cylinders offer unmatched dimensional stability and thermal inertness, making them essential for the most demanding metrology applications.

Standard sizes range from 200mm (7.87in) to 800mm (31.5") in height. Custom diameters, heights, and other special versions available upon request

- contact our engineering team for specialized configurations.

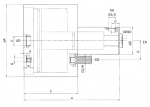

HLZ Tool Clamping Cylinders

HLZ hydraulic cylinders, in conjunction with spring actuated tool clamping and chucking devices, are intended for release and ejection of steep taper tooling and for stationary mounting.