Tool Changer Alignment Gauges

Tool changer alignment gauges are used to check automatic tool changer positioning between the gripper arm, magazine, tool holder, and the spindle.

Improper alignment results in abnormal wear on spindle and tool holder tapers, faulty clamping, dropped tools, and decreased machine repeatability – resulting in reduced productivity and expensive machine damage.

Tool changer alignment gauges from TAC Rockford make correct alignment between the spindle and automatic tool changer easy.

HSK Taper

Available for HSK-A 25, 32, 40, 50, 63, 80, 100, 125, and 160. Includes padded storage case.

PSK Capto

Available for Polygonal-Shank Taper sizes C3, C4, C5, C6, C8, C8X, C10. Includes padded storage case.

KM Taper

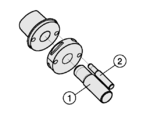

Tool changer alignment gauges verify proper alignment between the tool changer spindle. Improper alignment can result in abnormal wear on the spindle interface, tool changer, and tool holder. In addition, mis-clamping and dropped tools can also occur. KM gauges are available for ISO 26622 as well as Mazak Integrex flanges. Sets include taper and flange, axial and radial alignment pins, and a padded carrying case.