320.006

Gutekunst Spring Band Steel

We supply spring band steel either as pre-cut blanks or in coils with thickness values of 0.1 to 3.0 mm and widths of 2.0 - 120 mm. Available materials: 1.4310, 1.4301, C 75 S, C 100 S, CuSn6, CuZn37 as well as CuBe2

We supply spring band steel either as pre-cut blanks or in coils with thickness values of 0.1 to 3.0 mm and widths of 2.0 • 120 mm. Available materials:

1.4310, 1.4301, C 75 S, C 100 S, CuSn6, CuZn37 as well as CuBe2

The following dimensions and materials are always on stock (respectively in 1000 mm lengths).

A (soft): 600 N/mm2

B (hard): 1600 • 1800 N/mm2

C (rustproof): 1500 • 1700 N/mm2

Material A (soft) is to be hardened as follows:

1.) 5-minutes annealing at 820°C.

2.) Quenching in oil.

3.) 1-hour tempering at 400°C for RC 48 or a hardness of 1630 N/mm2.

4.) Air cooling.

For more information regarding this item (Gutekunst Spring Band Steel) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Spring Clips

Spring clips with a C in the front are made of CK 75 G without a galvanized surface plating. Upon request, we can offer galvanic surface. The spring clips with an X in the front are made of 1.4310 (stainless steel).

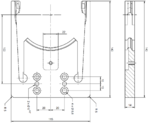

Standard-Duty Spring Steel Grippers

Standard duty spring steel grippers offer higher holding capacity and strength combined with a lower-cost design. Flexibility is maintained using a specialized spring steel and heat treat process. Grippers can be customized to meet specific mounting patterns. Contact us for taper sizes not shown.

Compression Springs Overview

Steel springs from Gutekunst are manufactured using spring steel wire material no.1.4310 in compliance with EN 10270 part 3 (AISI 302 / BS 301S21). The tolerances of the wire diameters comply with DIN 2076.

Vacuum Band Filters

Continuous purification of soiled cooling lubricants, as they are produced when operating machine tools. Purification of liquids from industrial washing plants and dust extraction plants and systems. It makes sense to use such a Vacuum Band filter with high throughput rates, because the throughput in a Vacuum Band Filter is 3 to 4 times higher than in a Gravitation Band Filter while the filtration area is identical. The Vacuum Band Filter consumes less filtration material.

Helical Disk Springs

With our patented helical disk spring, Roehrs can offer our customers a proven and tested machine component, which in many cases replaces the common multi-layer disc spring assembly.

Engine and Machinery Mounts

Steel-spring combination for high efficient shock and vibration absorption in order to avoid creep from elastomer springs and readjustment of machines respectively. We provide custom-designed mounts for all kinds of machines and engines (fixation on the side, straight fixation, universal fixation, fixation of the edge).

Special Multi-Characteristic Springs

Röhrs special springs with two characteristics are a specialty, in which two spring characteristics are combined into one spring.

Automatic Filter Devices

The soiled cooling lubricant is conveyed onto the non-woven filter lying in a cavity, via a liquid feed distributor. Owing to the gravitational force the coolant flows through the non-woven filter into a liquid container beneath the band filter. The dirt particles contained in the cooling lubricant are filtered out by the non-woven filter and accumulate in the form of a sludge cake on it. This causes a reduction of the permeability of the filter paper and, therefore, an increase of the liquid level above the filter cavity.