240.422

Comparison: Hydrostatic Leadscrews, Linear Motors, and Ballscrews

Comparison of hydrostatic leadscrews to linear motors and to ballscrews in metal cutting machinery

Design limitations and problems in ballscrew applications lead to the development of linear motors and to wear-free hydrostatic leadscrews. In this article we introduce the hydrostatic leadscrew system from HYPROSTATIK Schönfeld GmbH and compare its technical features with linear motor drives and ballscrews.

![]() PDF Data Sheet: Comparison: Hydrostatic Leadscrews, Linear Motors, and Ballscrews (240.422)

PDF Data Sheet: Comparison: Hydrostatic Leadscrews, Linear Motors, and Ballscrews (240.422)

Design limitations and problems in ballscrew applications lead to the development of linear motors and to wear-free hydrostatic leadscrews. In this article we introduce the hydrostatic leadscrew system from HYPROSTATIK Schönfeld GmbH and compare its technical features with linear motor drives and ballscrews.

Some users of machinery with linear motors get disillusioned or disappointed after the first enthusiasm with linear motors subsides. In contrast, hundreds of hydrostatic leadscrews are used in machinery for up to 7 years in 24 hour operations showing superior precision and 100% reliability.

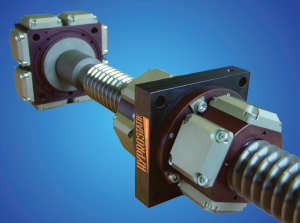

The Hydrostatic LeadscrewJust as a ballscrew does, the hydrostatic leadscrew transfers the rotation of a servomotor into linear motion. The hydrostatic nut floats on a thin oil film and is totally wear free. The thickness of the oil fi lm is kept constant by the unique Hyprostatik PM-flow controller and is independent of the load and speed. The clearance-free hydrostatic nut is extreme stiff, load independent, and has extreme low friction. At travels approaching zero [during positioning], the friction is too low to be measured and there is no torque increase during reversal. As a result the positioning precision, the smallest increments of movement, and the slowest speed are only limited by the machine controller system. Our hydrostatic leadscrew works like a shock absorber with excellent damping against vibrations caused by machining. Also, hydrostatic leadscrews work absolute noiseless and cause no vibration as can be experienced in ballscrew applications. Hydrostatic leadscrews are not limited in acceleration, nor in very slow movement, or in quick oscillating movements. Such applications can be done even under extreme loads. Standard hydrostatic leadscrews are available to rotate, or as rotating nut application in sizes 40 to 160 mm with max. Axial forces can be between 10 and 500 kN, speeds up to 120 m/min, and a total length to 5 meters. Different pitches and custom-made spindle ends can be designed. Hydrostatic bearings can be added, making the lead screw completely hydrostatic. In addition hydrostatic linear guides can be incorporated into the machine table.

Basic Physics in Machine ApplicationsElectric energy can be transferred effectively into motion with high speed and low torque. As a result, linear axis on machinery is equipped with high rpm motors and a leadscrew to get slow, precise linear movement with the high feed forces needed to operate a table. With high quality components, a machine table can be moved very sensitive with low forces.

The linear motor does not apply this principle of gear reduction. To get thigh linear forces, extreme strong magnetic fields must be employed. This is only possible to with very high electric current and/or coils with large inductivity. A magnetic field behaves like a mass. To change the linear force of the linear motor a change of the magnetic field is needed. This takes some time to do. This results in a delay once a linear motor needs to react to sudden external forces. This delay is much less severe in servo drives with leadscrews, since the magnetic fields and the current fl ow through the coils of the motor is a multiple less than with linear motors.

Stiffness at Static and Dynamic LoadsThe stiffness of the linear motor is controlled only by the positioning control of the drive and the resolution of the linear scale. Without the positioning control, the motor "floats".

Against static load the stiffness of the linear motor is extreme high, since errors are compensated. But the same feature is found with hydrostatic leadscrews, if a linear scale is used for position control.

The dynamic stiffness of the linear motor is low because of the delay in position measuring, reaction time of the control, and built-up of the magnetic field.

Linear motor producers give numbers for the dynamic stiffness of about 30N/micro-m at 100 kg slide weight and up to 120 N/micro-m at 600 kg slide weight are possible, without references to the frequencies. By the very low damping characteristics in moving direction, there is a danger of resonance at dynamic loads.

In comparison, the stiffness of the hydrostatic leadscrew system with 50 mm diameter and a working thread length of 400 mm is about 350 to 400 N/micro-m. The stiffness of the smallest nut and the leadscrew alone is more than 1500 N/micro-m. Together with the high damping and the higher total mass, the oscillation and dynamic position errors of the hydrostatic leadscrew are extremely reduced.

In addition, oscillating movement caused by external forces will die down much faster when using a design like the hydrostatic leadscrew with high damping characteristics instead of linear motors.

Acceleration FeaturesWith hydrostatic leadscrews as well as with linear motor there are no acceleration limits by the part design. The max. acceleration is limited by the moving masses and max. feed forces. The life of the hydrostatic leadscrew is independent of the max. acceleration. A servomotor needs to accelerate his own mass and the leadscrew. Nevertheless, modern servo motors can accelerate slides with a weight of 500 to 1000 kg and travel of 500 to 1000 mm with 16 to 34 m/s². An optimized system even higher acceleration is possible for short travel.

Feed ForceThe max. continuous feed force of the largest linear motors is about 8 kN, which is relatively low for a large machines. With hydrostatic leadscrews size 50, feed forces up to 20 kN and with size 160 up to 500 kN can be obtained even at highest speeds and over a long time without wear!

To summarize, a hydrostatic leadscrew can take much higher forces than the linear motor can. High loads, even at very slow speed, extreme high speed or oscillating moves do not influence the functional features nor live of hydrostatic leadscrews.

Speed FeaturesWith a hydrostatic leadscrew with 10 mm pitch 40m/min, or a pitch of 20 mm a speed of 80 m/min and with a pitch of 30 mm a speed up to 120 m/min can be obtained. For rotating spindles the max. rpm is limited only by the critical rpm, and not by the rotating nut.

The max. speed with linear motor depends on the type and is between 60 and 200 m/min for standard linear motors. The max. speed using a linear motor is also limited by safety factors in stopping the kinetic energy of the slide during sudden power outages. The table must be stopped at the end of the guideway by a properly designed bumper system.

What Max. Speed and Acceleration is Practical?In most machine tool applications, high speed and high acceleration is not needed during machining, but is needed to reduce non-productive times. Reducing non-productive time with acceleration above 10 m/s² makes no sense for average machines. It only makes sense if it is needed during machining, or at extreme short machining cycles per tool.

It makes much more sense to increase the speed from 20 to 40 m/min. An increase to 60 m/min requires a typical travel of over 400mm. Going over 80 m/min only makes sense if traveling distances over 800 mm are done often.

With hydrostatic leadscrews 20 m/s² acceleration and 120 m/min speed is possible, but for most machines lower speeds and lower acceleration make sense to get better machining results, longer machine life, reduced heat generation of the drive motor, and reduced energy requirements.

Energy Requirements, Heat Transfer, CoolingDuring typical machining, a tool is cutting with a feed rate of 0,1 to 0,4 m/min. For such machining high feed forces are needed.

The supplier of the linear motors with 6600 N feed force requires a cooling power of 5,4 kW, even at this low rate. To cool excess heat a chiller itself will need 2,1 kW power; or a total of 7,5 kW to cool a motor with 6600 N feed force.

A typical hydrostatic leadscrew for high speed requires an oil flow of about 2 l/min at 50 bar pump pressure. For the drive of the pump and the oil cooling with a simple oil-air cooler, a power of 0,45 kW is needed. At 0,4 m/min the servomotor needs about 0,14 kW to give 10000 N feed force at 50% efficiency. The total power demand of the axis with hydrostatic leadscrew with a higher feed force is 0,6 kW, which is 12 times lower and 6,9 kW lower than using the linear motor. At an average use of 2000 hours a year, the energy cost for linear motors are $ 750, and in three-shift operation $ 2250 per

year more.

The additional energy cost for a linear motor system over the average life of a machine is between $ 6250 and $ 18750 for one to three shift operation for each axis. When operating a number of machines with linear motors, the additional cost for the power supply system like additional transformer needs should be considered.

Since linear motors are located under the machine table, the enormous heat generated with the linear motor must kept away from the table with a water-cooled isolation barrier. Otherwise the machine accuracy might be compromised.

The servomotor for the hydrostatic leadscrew is normally placed at the end of the axis, therefore heat transfer to the table and guideways is very low. In most cases a fan on the servomotor is suffi cient; only in extreme applications water-cooling is necessary.

The energy input into the oil by the pump and friction of the hydrostatic nut is typically only about 60 to 120 Watt and is carried away from the machine table area with the oil. New oil is cleaning and cooling the leadscrew continuously. Only at very high speed or extreme high precision an air/oil heat exchanger is necessary.

Comparison to BallscrewsTo get acceptable life with ballscrews, high acceleration, high speed or short oscillating movements is not advisable. The ballscrew has low damping characteristics and will wear, which will lead to friction variation, stiffness and reversing features changes over the use of the machine.

In the case of a crash, the balls of the ballscrew may press a grove into the tracks, which might require premature exchange of the ballscrew. Since ballscrews are pre-stressed the drive torque needs to get to a certain level to get the spindle moving. The friction of the ballscrew varies when the ball enters and exits the nut. Because of this torque build-up at reversing and the torque variation, a precise positioning, small travels and slow movement with ballscrews is limited.

Problems of the Ballscrews are Eliminated by using Hydrostatic LeadscrewsThe acceleration has no design limit when using Force intensification effect of hydrostatic leadscrew and force compared to linear motor hydrostatic leadscrews. The nut can be adapted for the best application, by choosing the ideal oil viscosity, pressure and oil flow rate. The hydrostatic leadscrew will not wear; slow movement even under high load and oscillating motion are no problem even at the highest frequencies and oscillation. The damping of vibrations by the hydrostatic nut is extremely good.

Hydrostatic leadscrews are less likely being damaged during a crash when compared to ballscrews. Since the nut has contacts with the leadscrew on a large area, there is excellent lubrication. However even the hydrostatic screw could potentially be damaged in a severe crash.

Tests conducted at the University of Karlsruhe, Germany have shown that the stiffness of hydrostatic leadscrews is inherently higher than comparable ballscrews and characteristics do not change due to wear. The friction of the hydrostatic leadscrew is very low and proportional to the rotational speed. In addition, there is no friction at standstill and no torque-step during motion reversal as experienced on ballscrews. When hydrostatic bearings are used at the ends of the leadscrew and the slide has hydrostatic linear bearings as well, the servomotor does not need to overcome a stick slip force during starting. The hydrostatic drive and bearing system allows movement of the slide in steps and oscillation in fractions of microns and at extreme slow travel, independent of the weight, load, or cutting forces.

Vertical Axis and Power FailureDuring power failure, the linear motor must be stopped at the end of the stroke. Even with linear brakes, this is a problem because of high traveling speed. During a failure in the servomotor when using a hydrostatic leadscrew system, much higher break forces can be transferred. The hydrostatic leadscrew with a pitch of 10 mm is self-locking.

Ballscrews are not self-locking. On high dynamic axis, without weight counterbalance, the linear motor needs multiple more energy to carry the mass when compared with a hydrostatic leadscrew. Should a counterbalance weight be used the advantage at

acceleration is lost due to the increased mass.

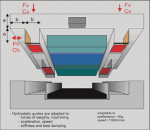

GuidewaysLinear bearings for the axis with linear motors are highly loaded by the continuos strong magnetic attraction force between the slide and the guideway. These forces also work when the machine is turned off. The attraction force varies and is typically 2 to 3 times larger than the max. short time feed force – [see above our comparison]. Together with the high speed and high acceleration, the life expectancy of ball or roller guides is reduced. Therefore when linear motors are used, wear free hydrostatic guideways should be considered as well.

Like in hydrostatic leadscrews, hydrostatic guideways are virtually wear free having 20 to 1000 times less friction, which is proportional to the speed and load. When reversing motion, there is no increase in feed force. As a result, with high quality drives and controls and full hydrostatic linear guides, test have shown that two 90 degrees angled slides can make circles with precision in the 0.1 micro-m area. This accuracy can lead to new machine concepts like jig boring machines or jig grinding machines.

Specialities of Linear Motors and Hydrostatic LeadscrewsSteel machining chips are attracted by the large magnetic fields of both linear motor parts and can result in malfunction. To eliminate the problem a proper shielding is requires with a sealed cover when linear motors are used. The assembly, maintenance and replacement of the linear motor, integrated in the slide, are much more expensive when compared with the externally mounted servomotor. A servomotor could be replaced without disassembling the slide.

Because of the strong magnetic fields of the linear motors, additional safety measure for protecting of persons with heart pacemaker, metal implants, and pregnant women, on the factory floor are required. In addition should magnetic stripes on credit cards, ID tags, watches, or computer disks come too close to the linear field; the programming might be destroyed.

The machine builder is limited on one producer of the linear motor, which often results in the need to use only one control. During assembly at the machine the high permanent attraction forces create problems: e.g. supplier of linear motors recommend to keep some non magnetic wedges available, which should be used to force the motor parts apart when needed.

The oil for the hydrostatic leadscrew must be returned to the tank. Return to the tank can be piped, supported by wipers at the nut ends, or with gravity together with the oil of the hydrostatic guides. For hydrostatic guides, leadscrew, and leadscrew bearings, one oil type with the same oil pressure of one hydraulic tank can be used. This oil could also lubricate other machine parts, or can be used for other hydraulic applications.

Linear motors must be designed into new machinery. Hydrostatic leadscrews can replace ballscrews with little design change. If the slightly bigger hydrostatic nut is considered during machine design, the machine can be offer with ballscrew or hydrostatic leadscrew.

Price ComparisonCompared with the ballscrew system, the cost for the hydrostatic leadscrew is higher. An accurate price comparison between hydrostatic leadscrews and linear motors depends on the design details.

In most cases the hydrostatic leadscrew with servo motor system is significantly cheaper compared with a linear motor design; which is essentially a result of cost of linear motor parts, cooling barriers, linear scale, periphery, sealed covers, and faster CNC-control. Also the redesign- or new design costs with adaptation to the machine structure increases the costs for a linear motor machine.

In most applications the use of hydrostatic leadscrews has reduced the cost for the machine user. We have seen hydrostatic leadscrews used in 3-shift operations for more than 5 years. They are still in as new condition. In comparison the ballscrews are changed yearly in the same type of machine.

Machines with a long strokes and linear motors get very expensive.

Typically we can assume that the linear drive with hydrostatic leadscrews and servomotor is typically cheaper than the drive system with a linear motor.

ApplicationsSeven years after the first use of hydrostatic leadscrews, many European camshaft, crankshaft, universal grinding machines, in ultra-precision and in gear grinding applications, heavy duty machines, the hydrostatic leadscrew is today a standard.

Eccentric machining or non-cylindrical machining up to 60 Hz at 3000 rpm at the workpiece is being realized. Hydrostatic leadscrews have been manufactured up to 5 meters long and for axial forces over 300 kN.

In most applications a hydrostatic leadscrew requires only one bearing. Only for long strokes, a second radial support is necessary.

Hydrostatic Guides with Hydrostatic Leadscrews and Hydrostatic Bearings – ConclusionWhen all the technical facts are considered we believe the use of hydrostatic leadscrew systems along with hydrostatic bearings and guideways are a proven alternative. In addition, when compared to the linear motor drive in high-speed application and to the ballscrew system in high force or high precision application is a better alternative.

Editors: Robert + Jochen Schönfeld

HYPROSTATIK Schönfeld GmbH

For more information regarding this item (Comparison: Hydrostatic Leadscrews, Linear Motors, and Ballscrews) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Hydrostatic Leadscrews

- Speed comparable to a linear motor

- Very low friction when machining, virtually frictionless

during positioning

- Steps in the 0.1 micron range are possible

- No backlash when reversing direction

Application: Hydrostatic Linear Motor Guide

Linear motors are used on high-speed machine tools with high acceleration and slide speeds. For slides with linear motors, HYPROSTATIK has developed hydrostatic guideways that have no wear, excellent damping characteristics, high stiffness and much lower friction when compared with ball or roller rails.

Hydrostatic Linear Motor Guide

The PM Flow Controller makes it possible for machine builders to easily integrate custom hydrostatic systems into both new and existing machines.

Application: Hydrostatic Rotary Tables

The world's largest gear and profile grinding machines use hydrostatic bearings.

CBN Hydrostatic Grinding Spindle Systems

This is an example of a hydrostatic spindle designed for high speed grinding with CBN grinding wheels. The small bearing diameter in combination with high surface speed allows the use of CBN wheels even for undercuts in a camshaft application.

Hydrostatic Application Worksheet

Download the PDF data sheet for the Hydrostatic Application Worksheet

LIFS Flat Linear Motors

Direct electric drive, high speed, without reduction gear, no play at direction reversal, no rotor losses, and with NdFeB magnets. Contact us to adapt the electrical and mechanical design to your specific requirements.

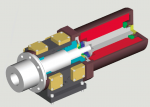

LINS Cylindrical Linear Motors

Direct electric drive, high acceleration, extremely low noise, without reduction gear, no play at direction reversal, free of lateral forces, no rotor losses, and with NdFeB magnets. Contact us to adapt the electrical and mechanical design to your specific requirements.

Hydrostatic Grinding Spindles with Integral Motors

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the

workpiece.

- Heat that is generated is moved immediately out of the spindle area with the oil and

cooled in the chiller.

- No vibration from roller bearings for extremely smooth operation.

- Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.