355.621.063.000

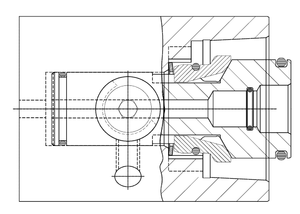

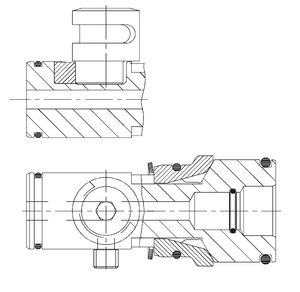

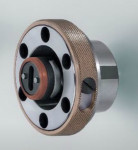

Rear-Clamp Cartridge for HSK-A/C/E63 and HSK-B/D/F80, Short Actuator Version

Rear manual clamping cartridges for HSK-A/C/E and HSK-B/D/F, Short Actuator Version

| Product | HSK Clamping Cartridge |

| Part Type | Manual Clamping |

| Taper / Standard | HSK-A/C/E |

| Taper Size | 63 |

| Part Number | ||||||||

|---|---|---|---|---|---|---|---|---|

| Rear-Clamp Cartridge for HSK-A/C/E32 and HSK-B/D/F40, Short Actuator Version | 355.621.032.000 | |||||||

| Rear-Clamp Cartridge for HSK-A/C/E40 and HSK-B/D/F50, Short Actuator Version | 355.621.040.000 | |||||||

| Rear-Clamp Cartridge for HSK-A/C/E50 and HSK-B/D/F63, Short Actuator Version | 355.621.050.000 | |||||||

| Rear-Clamp Cartridge for HSK-A/C/E63 and HSK-B/D/F80, Short Actuator Version | 355.621.063.000 |

For more information regarding this item (Rear-Clamp Cartridge for HSK-A/C/E63 and HSK-B/D/F80, Short Actuator Version) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Rear-Clamp Manual Clamping Cartridges

355.621 series manual clamping cartridges are suitable for HSK-E and HSK-F holders that do not have drive key slots or an access hole on the side of the taper. In addition, the center bolt is compatible with standard HSK coolant tubes.

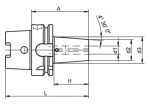

KS Adapter Flanges for Short Spindles

With radial alignment. Used for fitting into short spindles (DIN 69002) for holding HSK tools. Available for HSK-C 32, 40, 50, 63.

HSK-E Tool Holder Blanks

TAC Rockford stocks HSK-E32, HSK-E40, HSK-E50, and HSK-E63 blanks in a variety of diameters and lengths. Other sizes are available

- contact us with your requirements.

Self-Traveling Clamping Systems

Electromechanical PSP...VL/PLV Clamp for die clamping on slides. The clamp automatically travels between the park position and the actual die, guided by the T-slot of the slide. The bell-crank lever covers a wide clamping range.

HSK-A i-tec Shrink Fit Chucks Ultra Short Version

Available for HSK-A 63

Steep Taper (CAT/ANSI) to HSK Adapters

Adapts from CAT / ASME (ANSI) B5.50 (standard taper) to DIN 69063 (HSK taper).

HSK Tool Changer Alignment Gauges

Available for HSK-A 25, 32, 40, 50, 63, 80, 100, 125, and 160. Includes padded storage case.

Stationary Clamping Systems

The hydraulic die clamping system, PSP...HB, is designed to automatically clamp tools at the press slide or on the table. In the "Unclamped" position, the tensioning rod is completely retracted into the clamping element and initially moved out of the clamping element when pressure is applied.

Steep Taper (DIN) to HSK Adapters

Adapts from DIN 69871 (standard taper) to DIN 69063 (HSK taper). Maximum runout between steep and HSK taper is 0.003 mm.

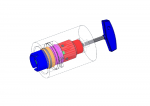

HSK Manual Clamping Grippers with Axial Drive

The Axialspanner comes for clamping disc-shaped tools (grinding wheels, saw blades) on HSK-flanges used. With low tension moments high clamping forces are generated, which are more than 50% above the recommended for HSK shanks values. Depending on the application of the AXS is centrally operated from the front through a tool flange or from the rear through the spindle.