293-HA

BERG Hydraulic Power Stations for Hydraulic Quick Die Clamping Systems

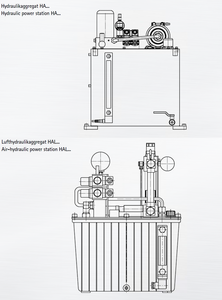

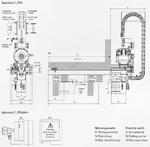

Hydraulic power stations for quick die clamping systems are designed for actuating hydraulic clamping elements in the forming presses. A large number of electro-hydraulic (HA) or air-hydraulic power stations (HAL) are available depending on the use of the clamping elements and/or hydraulics on the press plunger or on the table, as well as the number of clamping elements.

![]() PDF Data Sheet: BERG Hydraulic Power Stations for Hydraulic Quick Die Clamping Systems (293-HA)

PDF Data Sheet: BERG Hydraulic Power Stations for Hydraulic Quick Die Clamping Systems (293-HA)

ApplicationHydraulic power stations for quick die clamping systems are designed for actuating hydraulic clamping elements in the forming presses. A large number of electro-hydraulic (HA) or air-hydraulic power stations (HAL) are available depending on the use of the clamping elements and/or hydraulics on the press plunger or on the table, as well as the number of clamping elements.

Design FeaturesThe BERG electro-hydraulic units are always constructed as accumulator charging circuits and operate in intermittent operation with electronic pressure monitoring accordingly. Only the most high quality components are used. A differentiation is made between compact and add-on groups with a sub-oil pump depending on the necessary delivery volume. A hydraulic power station especially configured to meet the requirements of the clamping technology is used as an air hydraulic power station. The group operates independently, i.e. no pump control system is necessary.

Accessories/ServicesAll necessary components and systems such as configured connection hoses, oil sumps, control cabinet or the control station are available as accessories. As a service BERG offers the development and construction of complete hydraulic systems for retrofitting and customization.

For more information regarding this item (BERG Hydraulic Power Stations for Hydraulic Quick Die Clamping Systems) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Automatic Hydraulic C-clamping Systems

The C-clamping hydraulic die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the park position and the respective die. Hydraulic pressure is at a maximum 400 bar

Manual Hydraulic C-clamping Systems

The hydraulic C-clamp die clamping systems are designed for clamping tools and dies of different widths on press slides. The C-clamp is equipped with a non-return valve. The die clamps can be manually moved in the T-slot of the press slide between the parking position and the respective tool. Hydraulic pressure is at a maximum 400 bar.

Automatic Hydraulic Drawbar Style Clamping Systems

The hydraulic die clamping system with drawbar style clamping is designed for clamping dies of different widths on press slides. The clamping actuator moves automatically into the T-slot of the press slide between the parking position and the respective die. The clamping element can clamp different clamping rim heights due to the long clamping stroke of the double acting cylinder. Hydraulic pressure is at a maximum 400 bar.

Stationary Hydraulic Self-locking Swing-out Style Clamping Systems

Hydraulic, self-locking stationary swing-out style clamp for die clamping on slides and blackholders. When unclamping the draw bar swings out up to 15 degrees max.

Automatic Hydraulic Push Drive Chain-type Clamping Systems

The push drive chain-type hydraulic die clamping system is designed for clamping dies of various widths on press slides. The push-pull chain actuator moves automatically in the T-slot of the press slide between the parking position and the respective die. Hydraulic pressure is at a maximum 400 bar. The push-pull chain actuator can be used alternative to the PSV/PLV clamping actuator for every BERG press clamping system.

Manual Drawbar Style Hydraulic Clamping Systems

The drawbar style hydraulic die clamping systems are designed for clamping tools and dies of different widths on press slides. The BKZ-PS variant is equipped with a non-return valve. The BKZ-D (D = Double-acting) variant is intended for use in confined installation spaces where short clamping and/or release times are required. The BKZ-K (K = Cup) variant compensates for nonparallel tool clamping surfaces. The die clamps can be manually moved in the T-slot of the press slide between the parking position and the respective tool. Hydraulic pressure is at a maximum 400 bar.

Stationary Hydraulic Pull-back Rotational Style Clamping Systems

The hydraulic die clamping system with pull-back rotational style clamping is designed to clamp tools automatically at the press slide or on the table.

Manual Hydro-mechanical Self-locking C-clamping Systems

The hydromechanical self-locking (hydrolock) C-clamping die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator can be moved manually in the T-slot of the press slide between the parking position and the respective die. Hydraulic pressure is at a maximum 90 bar.

Automatic Hydro-mechanical Self-locking C-clamping Systems

The C-clamping hydromechanical self-locking (hydrolock) die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the parking position and the respective die. Clamping and unclamping are performed by a hydromechanical self-locking clamping gear. Hydraulic pressure is at a maximum of 90 bar.