319.000

Gutekunst Compression Springs Overview

Steel springs from Gutekunst are manufactured using spring steel wire material no.1.4310 in compliance with EN 10270 part 3 (AISI 302 / BS 301S21). The tolerances of the wire diameters comply with DIN 2076.

![]() PDF Data Sheet: Gutekunst Compression Springs Overview (319.000)

PDF Data Sheet: Gutekunst Compression Springs Overview (319.000)

MaterialPatented drawn spring steel wire in compliance with EN 10270 part 1 type DH for all wire diameters up to 1.9 mm. For diameters between 2.0 and 12.0 mm type SH will be used (AMS 5112 / BS 5216-75). Our steel springs are manufactured using spring steel wire material no.1.4310 in compliance with EN 10270 part 3 (AISI 302 / BS 301S21). The tolerances of the wire diameters comply with DIN 2076.

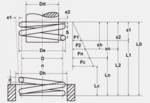

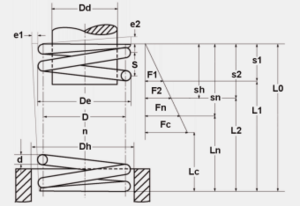

Finish and spring endsThe springs are right-hand coiled (clockwise). All springs have closed ends. Springs with larger wire diameters than 0.5mm are also closed and ground. All springs which show a tendency to set themselves (i.e. not to return to their original length after compression) are prestressed. All springs are ultimately thermally treated and stress relieved.

End coilsIn the catalogue the number of active coils is given in the column "n". The number of closed coils on the spring ends must be added to this figure. 1.5 or 2 coils will be added, depending upon the original number of active coils, so that the optimum 180° position of the end coil can be reached. However, an exact 180° position of the end coil cannot always be obtained, because a production compensation for the stated tolerances is carried out according to the number of active coils.

SurfaceSprings manufactured from spring steel EN 10270-1 type DH and SH are slightly lubricated following the thermal treatment. The springs can be delivered with any additional standard surface protection for an extra charge. Springs made of material no.1.4310 will not be re-coated after the thermal coating, as a surface protection is not normally required. The springs can be delivered with any additional standard surface protection for an extra charge.

Quality controlAll springs in our sales warehouse are quality controlled. This is carried out in our quality control department independent from the production process. The test for those springs destined for sale is carried out according to the DIN ISO 2859-1 inspection level II. The procedure normally consists of a simple spot check program, test-level AQL = 1.0. Every article tested recieves a test mark, which is recorded in the quality record book. All procedures are explained in our Quality Handbook, which we are happy to send to you if required. Standard springs are inspected for compliance to the stated tolerances. Specific tests can also be carried out and documented for each individual spring upon the customer's request. The following charges apply for the quality control certificates issued by us.

In compliance with:

EN 10204-2.1 (DIN 50049-2.1)

EN 10204-2.2 (DIN 50049-2.2)

EN 10204-2.3 (DIN 50049-2.3)

EN 10204-3.1B (DIN 50049-3.1B)

Testing of prototypes

Production CompensationProduction compensation is usually required in order to keep within the stated tolerances. (refer to DIN 2095 / 4.6) All the tolerance ranges of our standard sized springs are stated (coil diameter • DE, free length • L0, and maximum load • Fn.) These tolerances are maintained by varying the number of the active coils (n.) However, due to these measures the desired 180° position of the spring ends cannot always be obtained.

Setting the springsIn many cases compression springs are prone to ''set'' themselves. This means that the original free length of the spring (L0) can no longer be reached once the spring has been compressed to its solid length (Lbl), the spring has become shorter. This tendency can be prevented through a so-called scragging procedure. This allows the compression springs to return to the original free length ''L0'', when they are in a relaxed position, no matter what the application. All springs which show this ''setting" tendency because of their size are pre-set within the production process.

Spring designThe calculation and design of the springs is carried out in accordance with EN 13906, section 1.

Tolerances

The tolerances indicated correspond to the use of EN 15800 Grade 2 is used as standard, we can also supply all standard sized springs in Grade 1 for an extra charge.

Dynamic applicationThe spring data for the dynamic applications (Fndyn, Fndtol, Lndyn and shdyn) higher than 0.8 mm wire diameter are relevant only for springs having a shot peened hardened surface. Spring data for the dynamic applications up to a wire diameter of 0.75 mm are relevant without shot peened hardened surface. Please talk to our sales department if you need shot peened hardened surface for springs up to 0.75 mm wire diameter.

Dynamic application is required when:

a) the occuring expansion tension is greater than 10% of the maximum permitted torsion regarding the length "Ln".

For more information regarding this item (Gutekunst Compression Springs Overview) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Flat Wire Compression Springs

Compression springs made from flat wire

- wound to the spring axis

- offer the advantage of higher energy absorption at the same installation space compared to round wire compression springs. Furthermore, flat wire compression springs are more resistant to buckling and will encounter no friction martensite at high frequencies

-- unlike round wire compression springs, where the life expectancy is reduced. Our in-house rolling mills allow us to roll and process high-quality spring steels to the specific wire profiles our customers need. By choosing the right wire profile and spring dimensions, both linear and progressive characteristics can be realized.

Round Wire Compression Springs

Round wire compression springs are used in countless applications and fulfill / meet the widest range of technical requirements. We calculate the ideal spring design and select the appropriate spring material according to the load and environmental conditions. We can guarantee our customers the highest quality of our products.

Square Springs

We are your specialists in the manufacturing of square springs for industrial use. Our standard springs are made of 1.4310 material with a wire thickness of 1.0 mm. Other materials and thickness values are available at request.

Multi-Wire Springs

Multi-wire springs are made of wire strands with various strand structures and are put to use as compression, torsion, tension and form springs.

Tension and Torsion Springs

We are able to offer our customers tension, torsion and individual form springs made of round, square or flat wire as well as of strip steel for all kinds of applications.

Spring Combinations and Sets

Whenever a single compression, tension and helical disk spring alone does not meet the requirements, we individually design spring combinations and spring sets for our customers. By this means, we achieve significant successes regarding spring loads, operational safety, durability and installation length.

Helical Disk Springs

With our patented helical disk spring, Roehrs can offer our customers a proven and tested machine component, which in many cases replaces the common multi-layer disc spring assembly.

Special Multi-Characteristic Springs

Röhrs special springs with two characteristics are a specialty, in which two spring characteristics are combined into one spring.