Becoming a New Standard for Preventive Maintenance: Wireless Chuck Force Gauges

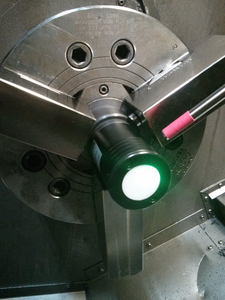

Since TAC Rockford's design of chuck force gauges using Bluetooth technology to communicate between a sensor and a display unit, machine users have found it a necessary tool as part of their PM (Preventive Maintenance) application. Besides only checking for drawbar force, machine users can have a display unit that connects to both a wireless drawbar and chuck force sensor, and operate seamlessly between them. More TAC Rockford's customers are realizing the potential for portable PM tools like the wireless chuck force gauge that integrate with the rest of ForceCheck.

What the wireless chuck force sensor will become

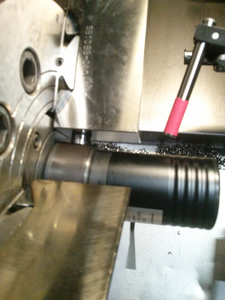

What was once a prototype for some customers, has now become a standard item for TAC Rockford, and is also being used for other custom "force and rotating" gauge applications. Force variations under rotating conditions have long been a highly unchecked combination for PM in machines and turning centers. The chuck force sensor acts as the "workpiece" and reports the exact forces and rotation a workpiece might encounter under load -- this allows for proper and crucial adjustments to workpiece-making parameters within machines.

Besides ForceCheck Drawbar Gauges checking only spindle-clamping forces, and otherwise the integrity and rigidity of tools to their core, the same conditions of the workpiece may also be checked.

Today, the design has incorporated a standard sensor-handle that can be adapted to any end-piece, whether chuck, collet, or tool taper. Generally, any custom designed end-piece (measurable with an equally balanced force load, whether compression or pulling-force) could be adapted to the ForceCheck sensor handle. Already, this has helped numerous customers who have provided schematics and designs of their custom applications, and a designed "inverted" end-piece can be engineered.

The software is custom, too

Besides inquiring about the physical aspects of TAC Rockford's custom force sensors (ForceCheck), the back-end with ForceCheck gauges have newer features as well as being compatible and interchangeable with the entire ForceCheck system. The sensor's software has even expanded beyond force-checking applications, and can be developed to various measurements. With ForceCheck, more data can mean more accuracy and a better understanding of machine maintenance.

Besides the ForceCheck display unit, TAC Rockford has also been designing a durable Android tablet to better organize data points of multiple machines and numerous types of sensors. As an example, the chuck force sensor would report a graph of force changes over time, and keep a history of captured data from a machine and sensor.