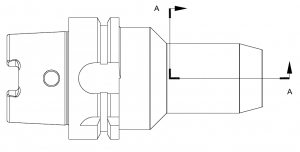

495.056

Hydraulic Collet Force Application Worksheet

Download PDF for worksheet.

![]() PDF Data Sheet: Hydraulic Collet Force Application Worksheet (495.056)

PDF Data Sheet: Hydraulic Collet Force Application Worksheet (495.056)

For more information regarding this item (Hydraulic Collet Force Application Worksheet) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Senso 3000 Hydraulic Tool Holder Force Gauge

The SENSO 3000 is a specialized tool for verifying correct operation of hydraulic tool holders. For workholding collet force gauges, please see our ForceCheck collet force gauges. SENSO 3000 determines the clamping force of the hydraulic chuck via a pressure sensitive plug gauge. The entire length of the plug gauge is clamped in the hydraulic chuck so that when tightening the clamping screw the clamping pressure of the chuck is optimally applied. The clamping force measuring instrument displays the clamping force as an absolute measurement value on the one hand and as a percentage clamping force in relation to a reference value that can be set individually on the other. This way, SENSO 3000 can be adapted to customer specific application conditions and requirements. The clamping force measuring instrument is supplied with a plug gauge for the respective clamping diameter as well as a carbide proofing bar for calibration purposes and a CR 2430 type battery – all in a sturdy and handy case.

Workholding Collet Drawbar Force Gauge

ForceCheck collet force gauges measure the drawbar pullback force of a 5C, 16C, or 20C collet workholding system. Measurement of collet drawbar force provides an easy way to ensure correct force from machine to machine, or between setups for different parts.

ForceCheck Workholding Collet Force Gauge

ForceCheck collet force gauges provide a quick and easy way to check force on collet workholding systems. <p>Applications for ForceCheck workholding collet force gauges include:</p> <ul> <li>Comparison of holding force between machines, allowing for consistent and repeatable production results regardless of mechanism (manual, hydraulic, or pneumatic)</li> <li>Periodic verification to assess if preventive maintenance is needed</li> <li>Establish correct holding force for running a particular part or job</li> <li>Determine optimal holding force for thin-wall, rings, and other parts sensitive to damage or distortion when machining</li> </ul> <p>A sensor is needed for each diameter to be measured. A ForceCheck base set with display is needed to display results (order separately).</p> <p>Sensors are also available in low-force versions. Contact us for further information.</p>

Collet Force Gauges

<b>The original ForceCheck collet force gauge has been replaced by application-specific versions. </b> <br> <b>For hydraulic tool holders and milling chucks:</b><br> <a href="https://tacrockford.com/product/gauges/force-check/hydraulic-tool-holder-force-gauges/">Series 495.250 ForceCheck Hydraulic Tool Holder Force Gauges</a> <br><br> <b>For workholding collets:</b><br> <a href="https://tacrockford.com/product/gauges/workholding/forcecheck-worholding-collet-force-gauge/">Series 495.245 ForceCheck Workholding Collet Force Gauge</a> <br><br> With the ForceCheck collet force gauge, the clamping forces on collets and hydraulic tool holders can be measured to obtain accurate machining specifications while fulfilling ISO standard requirements. Available in complete sets for 1/4, 1/2, 3/4, 1, 10 mm, 16 mm, 20 mm, 25 mm and other diameters. The ForceCheck collet force gauge allows tool holder and workholding collet holding force to be quickly and easily measured. <br><br> Because it is problematic to measure, this critical holding force is typically not checked, even though it plays an important role in manufacturing repeatability. <br><br> TAC Rockford, makers of the ForceCheck drawbar clamping measurement system, offers a simple, efficient, and consistently accurate collet force measurement unit. <br><br> With this system you can accurately and consistently measure the clamping forces on collets and hydraulic tool holders to obtain accurate machining specifications while fulfilling your company's or customer's ISO standard requirements. <br><br> Complete sets include a durable display with standard 9 volt battery, connecting cable, carrying case, and measuring bar. <br><br> Individual measuring bars for any size diameter are available.

Hydrostatic Application Worksheet

Download the PDF data sheet for the Hydrostatic Application Worksheet

ForceCheck ID (Inside Diameter) Collet Force Sensors

ForceCheck ID Collet Force Sensors are designed for use with internal gripping collets, chucks, and mandrels. Sensors are customized to the collet; please contact our engineering team with your collet specifications.

Helical Spring Design Worksheet

See PDF for Worksheet.

Application Information: ForceCheck Workholding Collet Force Gauge

<p><strong>Collet Force Operating Principle</strong></p> <p> </p> <p>We often get questions on the operating principle of the sensors. First a bit of explanation on what is really happening with a collet – a collet generates a force over a cylindrical area, which is ultimately a pressure. In practice, that pressure often varies at different locations along the axis of the collet. For example, with a 5C or collet that is segmented at the front and solid in the back, the pressure will be considerably higher to the front.</p> <p> </p> <p>In measuring force, our sensor measures at a single axis perpendicular to the axis of the collet. What is displayed is a "vector force" on that axis in Newtons or Pounds-Force. This is a snapshot of the whole collet that simplifies what is really happening but it provides a quick reference that will allow a user to compare different setups, machines, etc.</p> <p> </p> <p>Because of the way we’re measuring, the number displayed by the sensor generally can’t be directly correlated to the pressure gauge "on the back of the machine" due to the long chain of hydraulic/pneumatic/mechanical links between them.</p> <p> </p> <p><strong>Collet Force Accuracy/Repeatability</strong></p> <p> </p> <p>Several factors influence repeatability: friction in the system, mechanical advantage of the closer mechanism, inconsistencies between clamping cycles, collet diameter tolerances, sensor insertion orientation, etc. Because of the large number of variables, a user shouldn’t expect highly consistent repeatability. Generally we see something in the +/-10% but it can sometimes be significantly higher as the variables mentioned can fluctuate between clamping cycles.</p> <p> </p> <p>We recommend considering the collet force gauge as a comparison tool. For example, comparing the collet force between two machines with automatic systems. Another example would be variance in holding force between operators on a manual collet closer. Less important is the actual number measured; more important is a comparison between the numbers. Variance can be expected due to the multitude of variables at play: +/-10% is likely ok whereas 2x the force would be significant.</p> <p> </p> <p><strong>Common Use Cases for Collet Force Gauges</strong></p> <p> </p> <ul> <li><strong>Monitoring for changes in force over time:</strong> Changes can indicate mechanical problems, need for lubrication, etc.</li> <li><strong>Comparison between machines:</strong> To ensure consistent production, multiple machines running the same part can be adjusted to approximately the same force.</li> <li><strong>Job setup:</strong> Establish a "known good" holding force for running a specific job that can be easily re- set up next time the job is run.</li> <li><strong>Establish force for delicate parts:</strong> Holding force for thin-wall or other sensitive parts can be a balancing act between having sufficient holding force and distorting parts. The collet force gauge can help to establish an optimum force.</li> </ul> <p> </p> <p><strong>Contact us with questions</strong></p> <p>Please contact our Applications Engineering Team at 815 962-5600 with questions on your collet system. We are happy to assist in determining if our collet force gauges will help for your specific workholding challenges.</p> <p> </p> <p> </p> <p> </p>